Introduction

In modern industrial operations, forklifts are essential for material handling across construction sites, warehouses, and logistics centers. The reliability and performance of forklifts heavily depend on high-quality components, and choosing the right forklift part processing service is critical for operational efficiency.

Hengli, a leading modern metal processing enterprise, specializes in integrating the entire metal supply chain. With services spanning construction machinery, agricultural machinery, special vehicles, energy, and automotive components, Hengli provides high-quality, fast, and cost-effective forklift part processing solutions for clients in China and overseas, including North America and Europe.

This comprehensive guide explores laser cutting, welding, bending, forming, and powder coating processes for forklift parts, highlighting how Hengli’s advanced manufacturing capabilities ensure superior quality and efficiency.

1. Laser Cutting for Precision Forklift Parts

What is Laser Cutting?

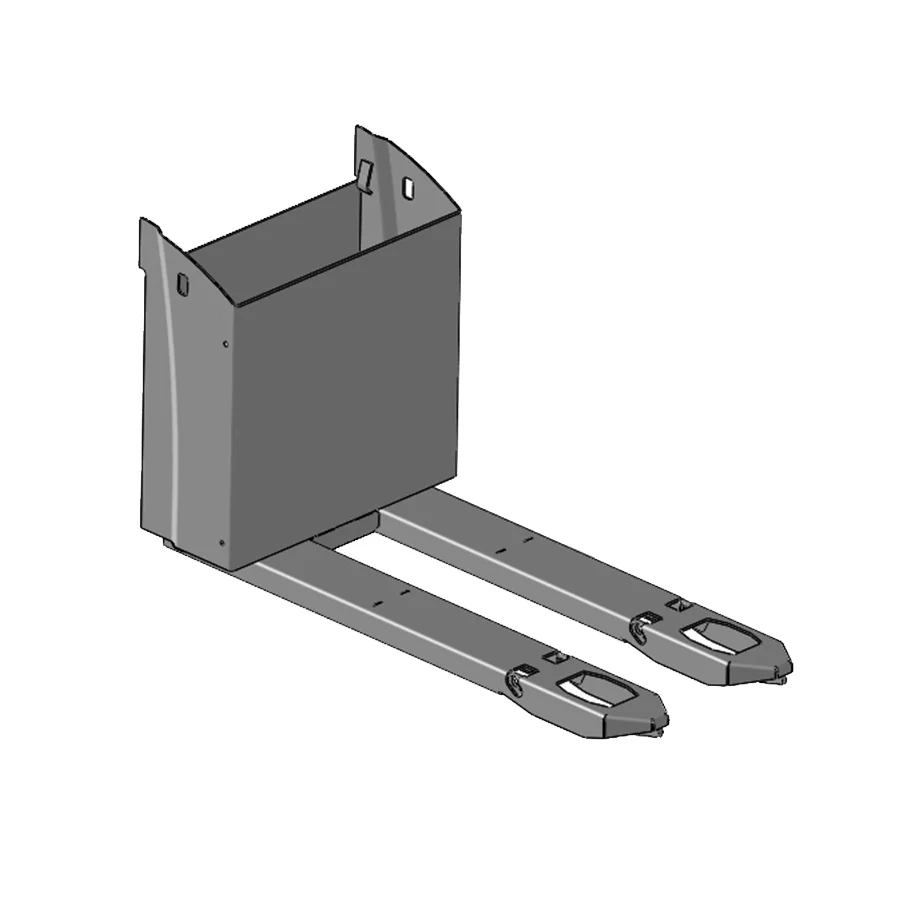

Laser cutting uses a high-powered laser beam to precisely cut metal sheets and components, creating complex shapes with minimal material waste. It is widely used for forklift chassis, forks, brackets, and other critical parts.

Advantages of Laser Cutting in Forklift Part Processing

-

High Accuracy: Achieves tight tolerances, reducing post-processing needs.

-

Speed: Automation allows high throughput, supporting short lead times.

-

Versatility: Works on stainless steel, aluminum, and other metals.

-

Cost-Effective: Minimal material waste lowers production costs.

Hengli Advantage: Automated laser cutting lines integrated with digital workflows ensure consistent precision and quality for every part.

2. Welding and Robot Welding for Durable Components

Types of Welding Services

-

Manual Welding: Ideal for small batches and customized forklift parts.

-

Robot Welding: Provides consistent and high-quality welds for high-volume production.

-

Specialized Welding Techniques: TIG, MIG, and seam welding for different metal types.

Benefits for Forklift Components

-

Enhanced structural integrity for chassis and forks

-

Compliance with international safety and quality standards

-

Improved durability for heavy-duty operations

Hengli Advantage: Combining skilled technicians with robot welding systems, Hengli delivers welded components with high load-bearing capacity and reduced defect rates.

3. Bending and Forming for Structural Integrity

Applications in Forklift Manufacturing

-

Fork arms, chassis frames, and reinforcement brackets

-

Custom brackets for special forklifts

-

Protective panels and structural supports

Why CNC Bending and Forming Matters

-

Ensures consistent angles and dimensions

-

Handles complex shapes without material compromise

-

Integrates seamlessly into automated production lines

Hengli Advantage: CNC-controlled bending machines deliver precise, durable parts while reducing production time and human error.

4. Powder Coating and Painting for Corrosion Resistance

Why Surface Protection is Essential

Forklift components are exposed to harsh environments, including moisture, chemicals, and mechanical wear. Powder coating and painting provide:

-

Durability: Scratch and chip resistance

-

Corrosion Protection: Extends lifespan of components

-

Aesthetic Finish: Smooth, uniform, and customizable

Hengli Advantage: Automated powder coating lines ensure even coverage, fast turnaround, and color consistency, meeting both functional and branding requirements.

5. Integrated Hengli Forklift Part Processing Workflow

| Process | Purpose | Hengli Advantage |

|---|---|---|

| Laser Cutting | Shape precision components | Automated CNC lasers with minimal waste |

| Flame/Plasma Cutting | Thick metal sections | High efficiency for heavy-duty parts |

| Bending/Forming | Structural shaping | CNC-controlled accuracy for consistent angles |

| Punching | Hole creation and slots | Fast, repeatable, and accurate |

| Welding/Robot Welding | Assembly of structural components | Consistent quality and load-bearing strength |

| CNC Machining | Precision finishing | Tight tolerances for functional parts |

| Powder Coating/Painting | Corrosion protection | Automated coating lines for durability and aesthetics |

| Galvanizing | Surface protection | Long-lasting anti-corrosion layer |

This end-to-end integration ensures short lead times, consistent quality, and reduced production costs.

6. Smart Factory Automation in Forklift Part Processing

Hengli leverages automation and digital management to improve efficiency and quality:

-

Automated Material Handling: Reduces human error and speeds production

-

Digitized Workflow: Seamless integration between cutting, welding, bending, and coating

-

Real-Time Quality Control: Ensures every component meets ISO and international standards

-

Traceability: Each part is tracked from raw material to finished product

Smart factory operations allow Hengli to deliver large volumes without compromising quality.

7. Applications Across Industries

Hengli’s forklift part processing services serve multiple sectors:

-

Construction Machinery: Heavy-duty chassis and fork structures

-

Agricultural Machinery: Reinforced frames for rough terrain

-

Special Vehicles: Custom components for industrial forklifts

-

Energy Sector: Components designed for harsh environmental conditions

-

Automotive Components: High-precision metal parts for forklift systems

These versatile services support global customers, ensuring forklifts operate safely and reliably.

8. Frequently Asked Questions (FAQ)

Q1: What metals can Hengli process for forklift parts?

→ Stainless steel, carbon steel, aluminum, and other industrial-grade metals.

Q2: Can Hengli handle both small and large batch production?

→ Yes, Hengli’s automated lines support high-volume manufacturing while maintaining quality in small orders.

Q3: How does powder coating improve forklift part lifespan?

→ It provides corrosion resistance, scratch protection, and a uniform finish that extends operational life.

Q4: Are Hengli’s services suitable for international standards?

→ Absolutely, all processes comply with ISO, CE, and international safety and quality standards.

Q5: What is the typical lead time for forklift part processing?

→ Lead time varies by complexity, but Hengli’s automated production lines allow for shorter turnaround times than traditional methods.

9. Conclusion

High-quality forklift components are essential for safety, efficiency, and durability. Hengli offers a complete, integrated range of forklift part processing services, including laser cutting, welding, bending, forming, CNC machining, and powder coating, supported by smart factory automation.

By partnering with Hengli, companies can achieve:

-

Reliable, long-lasting forklift parts

-

Fast production and delivery

-

Cost-effective solutions without compromising quality

-

Compliance with global industry standards

For businesses seeking precision, efficiency, and durability, Hengli is the trusted partner for all forklift part manufacturing needs.

www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd.