In today’s industrial environment, safety, efficiency, and operational reliability are paramount. One of the key components ensuring these priorities in complex systems is the mechanical valve interlock device. While standard interlock devices serve many industries effectively, there is an increasing demand for custom mechanical valve interlock devices designed to meet unique industrial needs. These custom solutions not only enhance safety but also improve process efficiency, compliance, and equipment longevity.

Understanding Mechanical Valve Interlock Devices

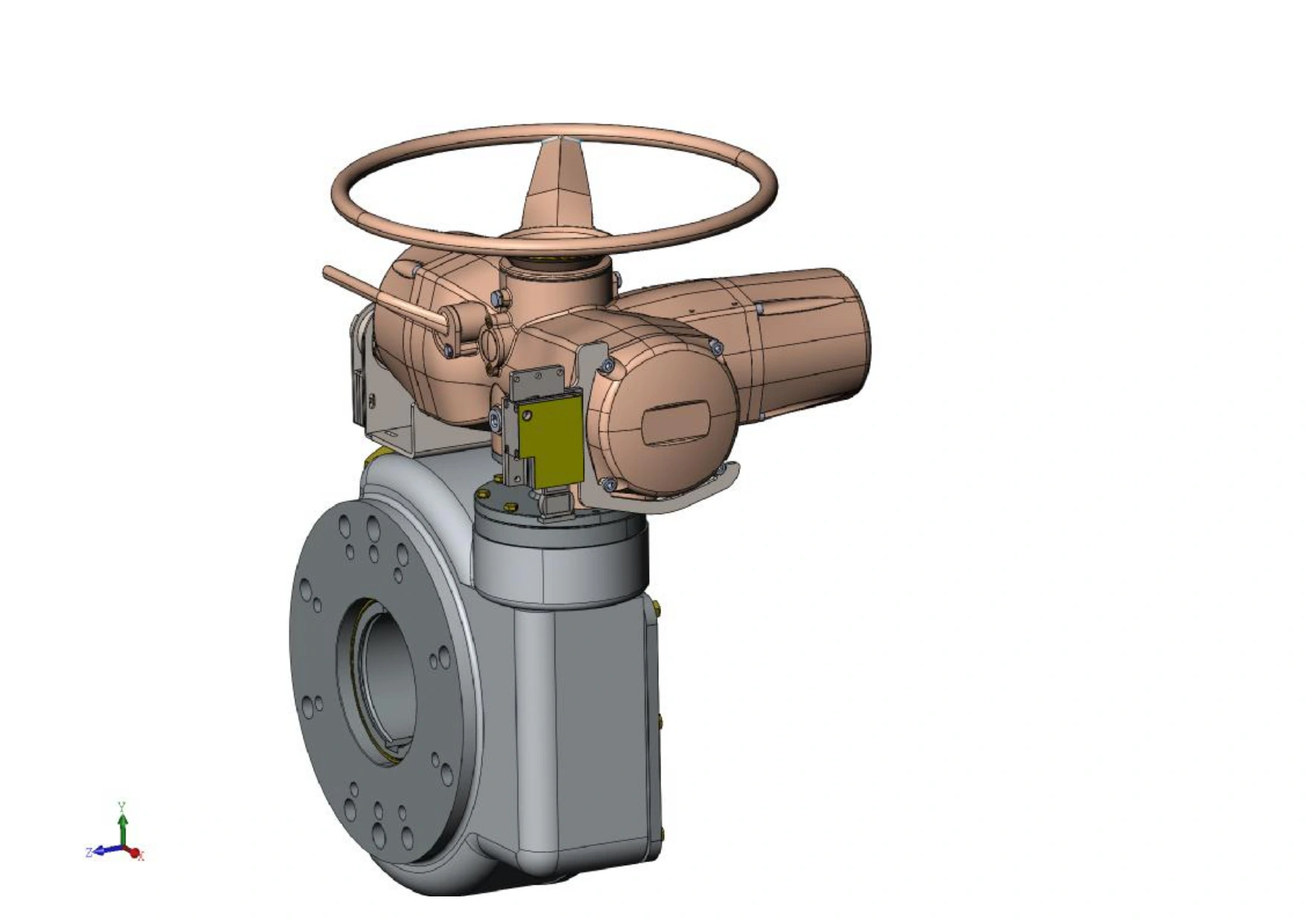

A mechanical valve interlock device is a safety mechanism that ensures valves in an industrial system operate in a predetermined sequence. By preventing the simultaneous or incorrect operation of valves, these devices reduce the risk of accidents, equipment damage, and operational errors. They are commonly used in industries such as chemical processing, oil and gas, water treatment, and petrochemicals.

Standard interlock devices are designed for common applications, but many industrial processes have unique requirements, such as unconventional valve arrangements, extreme operating conditions, or high-risk environments. This is where custom mechanical valve interlock devices become invaluable.

Why Customization Matters

Every industrial plant has its own operational challenges. Some facilities may operate under high temperature or pressure, while others require precise sequencing for safety-critical operations. Custom interlock devices are tailored to address these specific challenges. Here’s why customization is crucial:

-

Unique Valve Configurations

Many industrial systems have complex valve layouts that do not align with standard interlock designs. Custom devices are engineered to fit the exact valve positions and orientations, ensuring correct operational sequences without modifying the existing infrastructure. -

Extreme Operating Conditions

Some industries, such as chemical processing and petrochemical plants, involve corrosive substances, high-pressure steam, or extreme temperatures. Custom interlock devices can be manufactured from materials that withstand these harsh conditions, ensuring durability and safety. -

Compliance with Safety Regulations

Custom devices can be designed to meet or exceed specific local and international safety standards, such as OSHA, API, or ISO regulations. This is critical for industries where compliance audits are frequent and non-compliance can result in severe penalties. -

Integration with Existing Systems

Custom mechanical valve interlock devices can be seamlessly integrated with existing control systems, automation solutions, and operational protocols. This ensures minimal disruption and maintains system efficiency.

Key Features of Custom Mechanical Valve Interlock Devices

When designing a custom interlock device, several critical features must be considered to ensure optimal performance:

1. Material Selection

The device’s material must withstand the environmental conditions of the plant. Common choices include stainless steel for corrosion resistance, hardened alloys for durability, and specialized coatings for chemical resistance.

2. Locking Mechanism

The core function of any interlock device is its locking mechanism. Custom devices can feature mechanical locks, key-operated locks, or combination locks designed to enforce precise operational sequences.

3. Modular Design

Many custom devices are modular, allowing easy adaptation to different valve sizes and configurations. This modularity also simplifies maintenance and future upgrades.

4. Fail-Safe Operation

Custom devices often incorporate fail-safe designs that prevent unsafe operations in case of mechanical failure. This ensures that even in abnormal conditions, the system remains safe.

5. Adaptation for Automation

Modern industrial plants increasingly integrate automation systems. Custom mechanical valve interlock devices can be designed to work alongside pneumatic, hydraulic, or electronic control systems for enhanced operational control.

Applications Across Industries

Custom mechanical valve interlock devices are widely used across industries with specialized operational needs:

Chemical and Petrochemical Plants

In chemical plants, incorrect valve operations can cause dangerous reactions or environmental hazards. Custom interlock devices ensure the safe sequencing of chemical feeds, isolation valves, and emergency relief systems.

Oil & Gas Industry

Oil refineries and gas processing facilities often operate under high pressure and extreme temperatures. Custom devices made from robust materials prevent accidental mixing of incompatible fluids and ensure proper valve sequencing in critical pipelines.

Water and Wastewater Treatment

Water treatment systems often involve multiple valves for chemical dosing, filtration, and pumping stations. Custom interlocks help operators maintain proper sequences, reducing the risk of contamination or overflow.

Power Generation

In power plants, interlock devices are critical for steam, cooling, and fuel systems. Custom designs ensure safety during maintenance shutdowns, startup sequences, and emergency operations.

Benefits of Custom Mechanical Valve Interlock Devices

Investing in custom interlock solutions provides multiple advantages:

-

Enhanced Safety: Custom devices prevent human errors and equipment failures, protecting personnel and assets.

-

Improved Operational Efficiency: Proper sequencing reduces downtime and avoids costly accidents.

-

Longevity and Reliability: Devices tailored to specific operating conditions last longer and require less maintenance.

-

Regulatory Compliance: Custom solutions help facilities adhere to industry regulations and standards.

-

Flexibility: Modular designs allow adaptation for future plant expansions or process changes.

Case Study: Custom Interlocks in a Chemical Plant

A chemical manufacturing facility faced repeated issues with accidental valve operation during high-pressure reactions, leading to near-miss incidents. Standard interlock devices could not accommodate the facility’s unusual valve layout. By designing custom mechanical valve interlock devices, engineers created a system that matched the plant’s unique configuration, included fail-safe mechanisms, and used corrosion-resistant materials. The result was a significant reduction in operational errors and improved overall plant safety.

Choosing the Right Manufacturer

When sourcing custom mechanical valve interlock devices, it is essential to select a manufacturer with expertise in industrial safety solutions. Key considerations include:

-

Experience in designing interlock devices for specific industries

-

Ability to provide material and mechanical customization

-

Strong testing and quality assurance processes

-

Support for installation, maintenance, and future upgrades

Conclusion

In industrial systems where safety, efficiency, and compliance are critical, custom mechanical valve interlock devices offer a tailored solution to unique operational challenges. By addressing specific valve configurations, environmental conditions, and regulatory requirements, these devices enhance safety, reduce downtime, and improve operational reliability.

Whether in chemical processing, oil and gas, water treatment, or power generation, custom interlock solutions are indispensable for modern industrial operations. Investing in these devices not only protects personnel and equipment but also ensures long-term operational success.

www.nudango.com

nudango