Precision is the backbone of modern machining. Whether producing gears, flanges, turbine components, or complex indexed parts, manufacturers are under constant pressure to deliver tighter tolerances, better surface finishes, and higher consistency. One tool that plays a decisive role in meeting these demands is the rotary table for dividing disk. Though often seen as a traditional accessory, its impact on machining accuracy remains highly relevant in today’s CNC and automated production environments.

This article explains how a rotary table for dividing disk improves machining accuracy, how it is applied in real manufacturing scenarios, and why choosing the right supplier matters. We will also briefly introduce Sichuan Zhongxin Rotating Machinery Equipment Co., Ltd., a Chinese manufacturer with extensive experience in rotary and customized automation equipment.

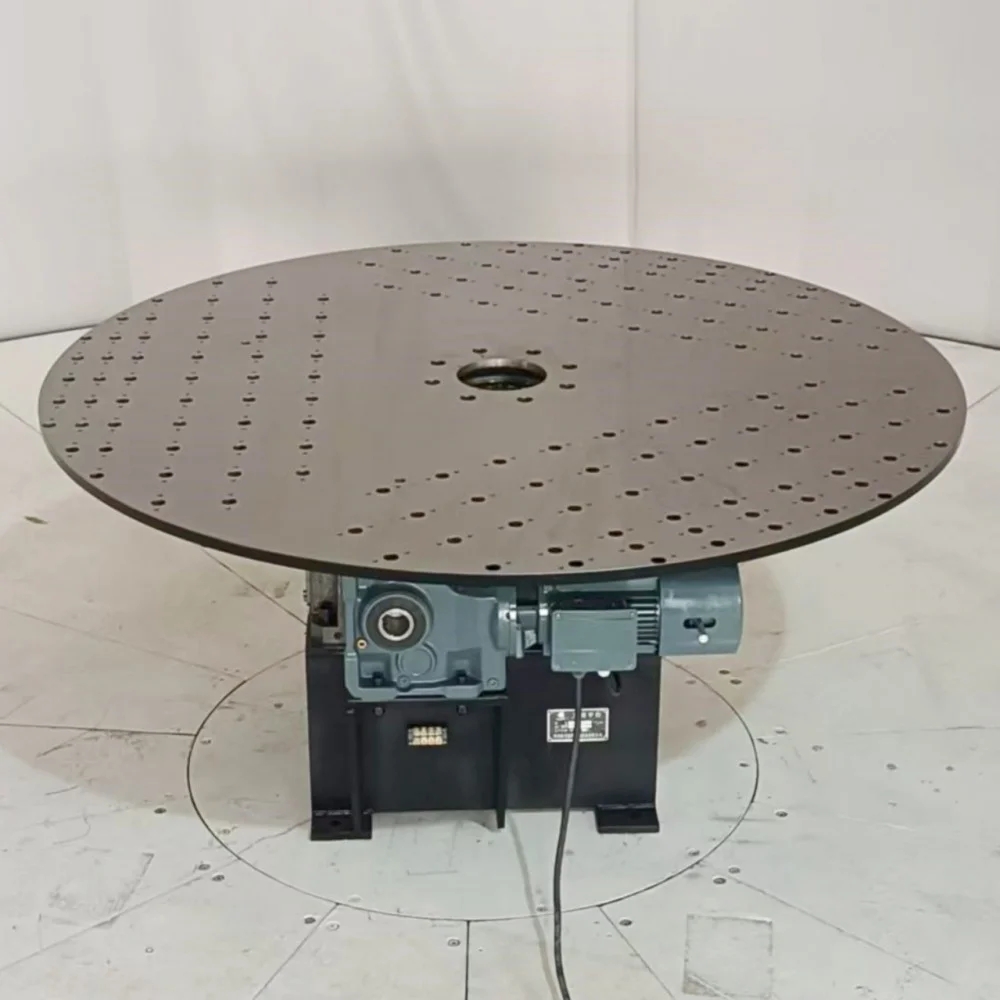

Understanding the Rotary Table for Dividing Disk

A rotary table for dividing disk is a precision mechanical device used to rotate a workpiece by a fixed angle for each machining operation. By indexing the part at exact increments, the machine tool can perform evenly spaced cuts, holes, or features around a circular workpiece.

Unlike manual positioning or rough indexing methods, a dividing disk provides predefined angular divisions. These divisions are engraved or machined with high precision, ensuring that each rotation step is repeatable and accurate. This is especially important in operations such as:

-

Gear cutting

-

Slot milling

-

Hole drilling on circular patterns

-

Polygon machining

-

Multi-face part processing

The rotary table works as a positioning reference, transforming rotational motion into controlled, predictable angular movement.

Why Machining Accuracy Depends on Indexing Precision

Machining accuracy is not only about spindle speed or cutting tools. Positional accuracy plays an equally critical role. Even small angular deviations can result in:

-

Uneven tooth spacing in gears

-

Misaligned bolt holes

-

Imbalanced rotating parts

-

Increased vibration and wear

A rotary table for dividing disk directly addresses these risks. By fixing angular positions mechanically, it removes uncertainty from the indexing process.

Key accuracy improvements include:

1. Consistent Angular Positioning

Each division on the disk represents a precise angle. When the table locks into position, the workpiece is held firmly at that angle. This mechanical certainty eliminates cumulative errors that can occur with manual measurement or repeated recalibration.

2. Reduced Operator Dependence

Manual indexing often relies on the operator’s experience and judgment. A dividing disk standardizes the process. Once set up correctly, the same angular accuracy can be achieved across shifts and operators, improving overall process stability.

3. Improved Repeatability

Repeatability is essential in batch production. A rotary table ensures that every part in a production run is indexed in exactly the same way, which directly improves part-to-part consistency.

How Rotary Tables Improve Accuracy in Real Applications

To better understand the practical value of a rotary table for dividing disk, let’s look at several common machining applications.

Gear Manufacturing

Gear cutting demands extremely accurate tooth spacing. Any angular error can cause noise, vibration, or premature failure. Using a dividing disk allows machinists to index the gear blank precisely for each tooth, maintaining uniform spacing and correct meshing performance.

Flange and Bolt Circle Machining

In flanges and structural components, bolt hole patterns must align perfectly. A rotary table ensures that each hole is drilled at the exact angular position, reducing assembly issues and rework.

Multi-Face Machining

For parts requiring machining on multiple faces, the rotary table enables accurate repositioning without removing the workpiece. This reduces setup errors and maintains alignment between features.

Mechanical Stability and Rigidity Matter

Accuracy is not only about angular divisions. The rigidity and structural quality of the rotary table itself significantly influence machining results.

A well-designed rotary table for dividing disk offers:

-

High load-bearing capacity

-

Minimal backlash

-

Stable locking mechanisms

-

Smooth rotation without vibration

These factors ensure that the workpiece remains stable during cutting, even under heavy loads or aggressive machining conditions.

Manufacturers that specialize in large and medium-sized rotary platforms often focus heavily on these mechanical aspects, as they directly affect long-term accuracy and service life.

Integration with Modern CNC Systems

Although dividing disks have a long history, they are far from outdated. Today, many rotary tables combine traditional mechanical indexing with CNC control systems.

This hybrid approach offers several advantages:

-

Mechanical indexing for high reliability

-

CNC positioning for flexible programming

-

Faster setup times

-

Compatibility with automated production lines

For manufacturers producing complex parts in medium or high volumes, this combination delivers both accuracy and efficiency.

Selecting the Right Rotary Table Supplier

Not all rotary tables are created equal. Accuracy on paper does not always translate to accuracy on the shop floor. Choosing an experienced manufacturer is essential, especially for customized or large-scale applications.

Sichuan Zhongxin Rotating Machinery Equipment Co., Ltd. is one such manufacturer with a long development history. Originally established as Shanghai Zhongxin Machinery Manufacturing Plant in June 2010, the company expanded with the founding of its Deyang production base in Sichuan Province in June 2017.

Deyang is known as a heavy industry city in China, making it an ideal location for producing large rotary tables and non-standard automation equipment. As the company’s main production base, the Deyang facility efficiently serves both domestic and international customers.

Product Range and Technical Capabilities

Sichuan Zhongxin Rotating Machinery Equipment Co., Ltd. offers a wide range of products and services, including:

-

Industrial rotary tables

-

Automotive rotary platforms

-

Large rotating platforms

-

Rotary display stands

-

Artistic mechanical installations

-

Non-standard automation equipment

This diverse product portfolio allows the company to support various industries, from traditional machining and automotive manufacturing to exhibition and custom mechanical systems.

By focusing on design, manufacturing, and application integration, the company can tailor rotary table solutions to specific machining accuracy requirements rather than offering one-size-fits-all products.

Global Experience and Practical Feedback

Accuracy improvements are not theoretical; they are validated through real-world use. Zhongxin’s rotary products have been exported to more than ten countries, including the United States, the United Kingdom, Qatar, Singapore, and Russia.

Different markets bring different technical standards and application challenges. Serving international customers helps refine product design, quality control, and reliability, all of which directly influence machining accuracy.

Practical Considerations When Using a Dividing Disk Rotary Table

To fully benefit from a rotary table for dividing disk, manufacturers should pay attention to several practical points:

-

Proper installation and alignment with the machine tool

-

Regular inspection of locking and indexing components

-

Matching table load capacity to workpiece weight

-

Choosing suitable indexing increments for the application

When these factors are managed correctly, the rotary table becomes a long-term accuracy-enhancing asset rather than just an accessory.

Reference Link for Further Technical Details

For readers looking for more detailed specifications and application examples, the following anchor link provides focused information on this type of equipment. The anchor text is embedded in code form as requested:<a href="https://www.zxzht.com/rotary-table-for-dividing-disk.html">

rotary table for dividing disk</a>

www.zxzht.com

Sichuan Zhongxin Rotating Machinery Equipment Co., Ltd.