In the competitive world of vertical transportation, the importance of smooth, safe, and efficient door operation cannot be overstated. Among the diverse range of elevator door mechanisms, the six panel center opening elevator door operator has emerged as a cutting-edge solution that blends functionality, aesthetics, and advanced control. With a sophisticated panel structure and optimized kinematic coordination, this type of operator significantly improves accessibility, space utilization, and reliability, especially in high-demand and high-capacity installations. This article Optimax delves deep into the advantages of the six panel center opening elevator door operator, providing comprehensive insights for engineers, architects, and industry professionals.

What is the Six Panel Center Opening Elevator Door Operator?

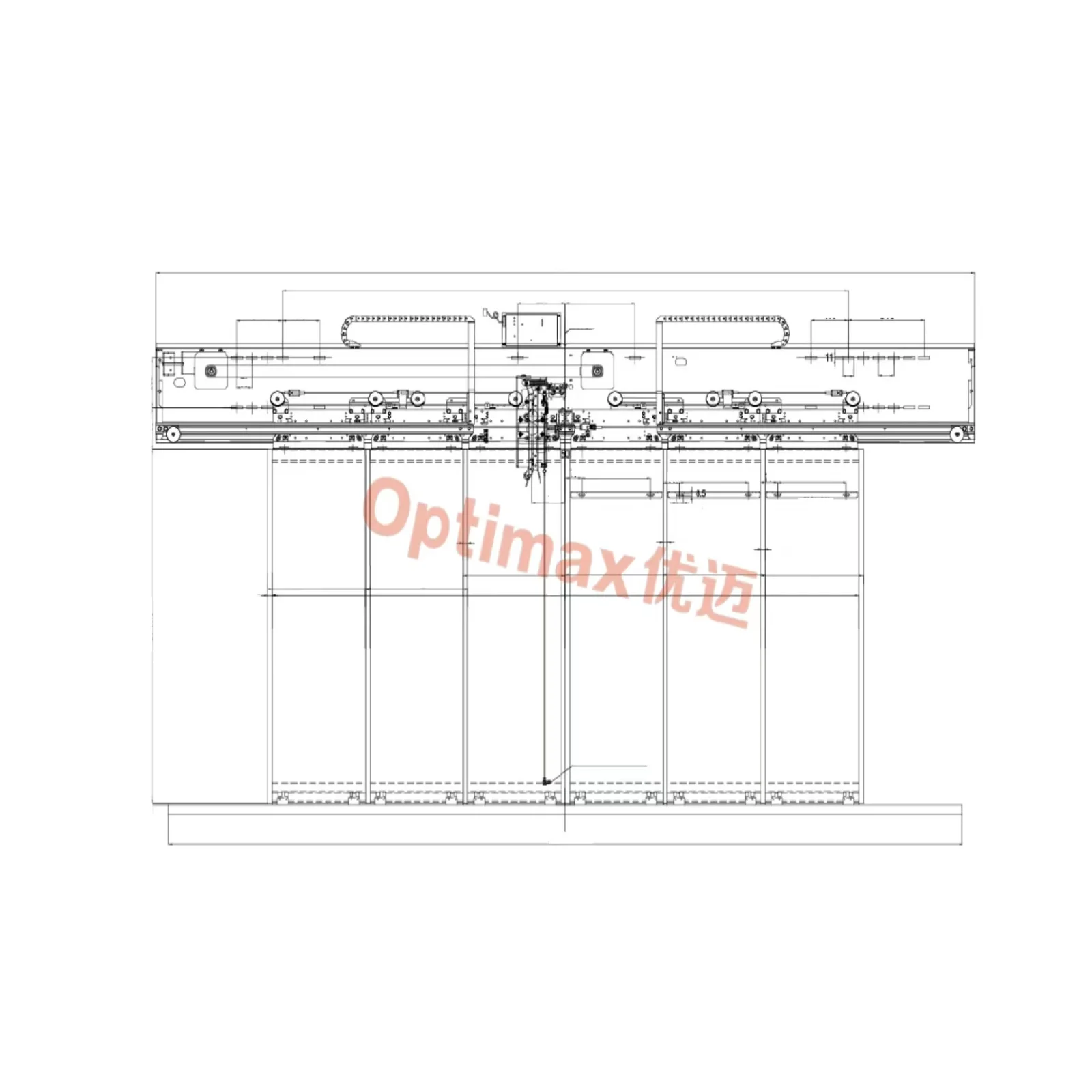

At its core, a six panel center opening elevator door operator is designed to divide the total opening into six door leaves—three on each side—that slide symmetrically from the center toward the sides when opening. The panels are driven by a single or dual motor system through linkages and belt or gear-based transmission mechanisms. Each panel moves in coordinated motion, offering seamless and balanced operation.

This architecture differs significantly from conventional two- or four-panel center-opening doors by allowing for wider openings without compromising door thickness or requiring additional shaft space. The increased number of panels helps reduce individual panel width, which minimizes the required pocket depth for door retraction. This is especially beneficial in situations where maximizing cabin space and maintaining clear access are priorities.

The six panel center opening elevator door operator enables smoother passenger flow in busy environments such as transit hubs, shopping malls, and commercial complexes. The modular design of the system also simplifies replacement and servicing of individual panels, enhancing its appeal to facility managers and maintenance teams.

Six Panel Center Opening Elevator Door Operator Advantages

The six panel configuration presents several key advantages that elevate it above traditional models in terms of performance, longevity, and user experience.

Wider Clear Opening with Minimal Shaft Space Requirements

The six panel center opening elevator door operator maximizes the usable door opening without increasing the required shaft width. By dividing the full width across six narrower panels—three retracting on each side—the system creates a wider clear entryway while maintaining compact installation dimensions. This approach is ideal for space-constrained environments such as older buildings or narrow shafts, where maximizing passenger access without expanding the shaft is critical. Designers benefit from increased layout flexibility, and users experience smoother traffic flow, especially in high-traffic areas or where accessibility is a concern.

Improved Kinematic Balance

One of the core engineering advantages of the six panel center opening elevator door operator is its superior kinematic balance. Unlike traditional two-panel systems, which impose significant torque on fewer moving components, the six-panel layout distributes motion evenly across all panels. This reduces mechanical stress on the motor and structural supports, resulting in quieter operation, less vibration, and significantly lower wear and tear. The balanced motion also supports consistent door speeds and reduced acceleration shocks, enhancing long-term durability and comfort for passengers during door transitions.

Enhanced Safety Through Redundancy and Synchronization

Safety is paramount in elevator systems, and the six panel center opening elevator door operator meets high standards through precise synchronization and built-in redundancies. Each of the six panels is monitored by advanced sensors and encoders that feed real-time data into the control system. If one panel encounters an obstruction or moves out of sync, the operator can immediately halt or reverse movement to prevent accidents. This level of intelligent response, coupled with hardware redundancy, ensures safe and reliable door operation even in demanding environments such as hospitals, airports, or high-rise towers.

Energy Efficiency and Low Power Consumption

Despite handling more moving parts, the six panel center opening elevator door operator is optimized for energy efficiency. Its design allows the workload to be shared across multiple panels, reducing the strain on each motor and lowering overall power consumption. Modern versions also incorporate regenerative braking systems that convert excess kinetic energy into reusable electrical power during deceleration. Additionally, smart motor controllers adjust energy usage based on real-time demand, making this system not only powerful and reliable but also aligned with green building standards and long-term operational cost savings.

The six panel center opening elevator door operator represents the next level of performance in door system design. With its blend of mechanical innovation, intelligent control, and architectural flexibility, it is well-positioned to meet the growing demands of modern vertical transportation. By delivering wide access, operational reliability, and a high degree of customization, this operator is setting new benchmarks in elevator door technology. Whether it's enabling patient transport in hospitals, supporting logistics in industrial facilities, or enhancing aesthetics in high-end commercial towers, the six panel center opening elevator door operator offers a robust and elegant solution for future-ready buildings.

https://www.xizi-ec.com/The-Rise-of-the-Six-Panel-Center-Opening-Elevator-Door-Operator.html

https://www.xizi-ec.com/JC-6C146EA-Center-Open-Six-Panel-Door-System.html

www.xizi-ec.com

Hangzhou Optimax Tech Co., Ltd.