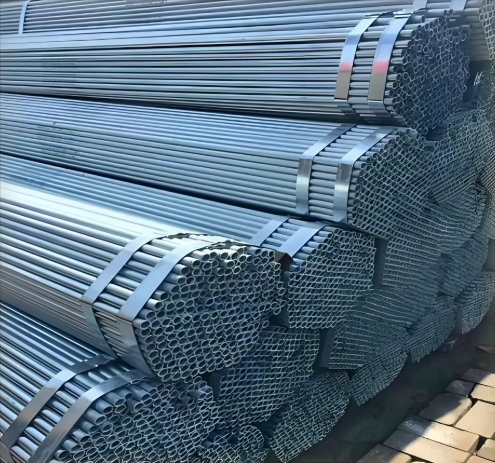

In the world of construction and infrastructure development, materials that combine strength, durability, and cost-effectiveness are essential. One such material that continues to play a significant role across industries is galvanized steel pipe. From residential water supply systems to massive urban infrastructure projects, galvanized steel pipes have stood the test of time as a reliable choice for conveying fluids, supporting structural frameworks, and ensuring long-lasting performance.

This comprehensive guide explores the importance of galvanized steel pipes in modern infrastructure and water supply systems. We will delve into their unique properties, benefits, applications, and what to consider when choosing the right galvanized steel pipes. Additionally, we highlight Guangqi, a prominent manufacturer specializing in galvanized steel pipes and a wide range of pipe products, for their contributions to global infrastructure solutions.

What Are Galvanized Steel Pipes?

Galvanized steel pipes are steel pipes that have been coated with a layer of zinc to prevent corrosion and rust. This process, known as galvanization, creates a protective barrier that significantly extends the pipe's lifespan, especially in environments exposed to moisture or harsh weather conditions.

There are two common methods of galvanization:

Hot-Dip Galvanizing: The steel pipe is submerged in molten zinc, creating a strong, durable coating.

Electro-Galvanizing: A thinner zinc coating is applied using electrolysis.

Hot-dip galvanizing is the most commonly used method for infrastructure and water systems due to its superior durability and resistance to corrosion.

Importance of Galvanized Steel Pipes in Modern Infrastructure

Corrosion Resistance

Galvanized pipes provide exceptional protection against rust, making them ideal for water and wastewater systems, outdoor applications, and areas with high humidity.

Strength and Structural Integrity

Steel offers high tensile strength, and the added zinc coating enhances its durability, making galvanized steel pipes suitable for load-bearing structures and underground installations.

Long Service Life

When properly installed and maintained, galvanized pipes can last several decades, reducing the frequency of replacements and maintenance costs.

Cost-Effective Solution

Compared to stainless steel or other corrosion-resistant alloys, galvanized steel is more affordable while still providing excellent protection.

Versatility

These pipes can be used in a wide range of applications, from plumbing to structural support, fencing, and even automotive industries.

Applications of Galvanized Steel Pipes

Water Supply and Distribution Systems

Galvanized pipes are extensively used in water supply networks due to their corrosion resistance and ability to withstand high pressures.

Urban Infrastructure Projects

From bridges to handrails and guardrails, galvanized pipes provide essential structural support in cities worldwide.

Agricultural Irrigation Systems

Their resistance to rust and environmental degradation makes them ideal for irrigation pipelines.

Oil and Gas Industry

Galvanized pipes are used in specific low-pressure applications for oil and gas transmission.

Construction and Housing

They are often used in scaffolding, fencing, and frameworks for residential and commercial projects.

Advantages of Galvanized Steel Pipes

Durable Protection

The zinc coating acts as a sacrificial layer, meaning even if the surface is scratched, the surrounding zinc will protect the exposed steel.

Minimal Maintenance

Once installed, galvanized pipes require very little upkeep compared to uncoated steel.

Readily Available and Standardized

Galvanized steel pipes are widely produced in standard sizes, ensuring easy integration into existing infrastructure.

Sustainable and Recyclable

Steel is a recyclable material, and galvanization extends its usable life, contributing to sustainable construction practices.

Cost Efficiency Over Time

Although the upfront cost is slightly higher than untreated steel, the reduced maintenance and long lifespan provide better cost-effectiveness in the long run.

Key Factors to Consider When Choosing Galvanized Steel Pipes

Pipe Size and Wall Thickness

The size and wall thickness should be selected based on the intended application and pressure requirements.

Quality of Zinc Coating

Thicker and evenly applied coatings provide better corrosion resistance.

Compliance with Industry Standards

Ensure the pipes meet relevant standards such as ASTM, ISO, or EN specifications for safety and performance.

Environmental Conditions

Consider the exposure to chemicals, humidity, or seawater, as these factors affect the longevity of galvanized pipes.

Supplier Reliability

Choose a reputable supplier like Guangqi, known for its strict quality control, advanced galvanization techniques, and global distribution network.

Guangqi: A Trusted Manufacturer of Galvanized Steel Pipes

Guangqi is a leading manufacturer and supplier of high-quality galvanized steel pipes and a wide range of piping materials designed for infrastructure, construction, and water systems. Their products are widely recognized for their durability, precision, and compliance with international standards.

Why Partner with Guangqi?

Advanced Manufacturing Facilities: Equipped with cutting-edge galvanization technology.

Strict Quality Assurance: Comprehensive inspection processes from raw material to finished product.

Diverse Product Range: Offering pipes in various sizes, wall thicknesses, and specifications.

Global Export Experience: Serving markets in Asia, Europe, North America, and beyond.

Sustainability Commitment: Environmentally friendly production processes and recyclable materials.

Installation and Maintenance Best Practices

Installation Tips:

Always inspect pipes for damage before installation.

Use compatible fittings and connections to prevent galvanic corrosion.

Avoid welding galvanized pipes when possible; if necessary, apply zinc-rich paint to welded areas.

Maintenance Guidelines:

Periodically inspect exposed pipes for signs of corrosion.

Clean any deposits or buildup that may accelerate wear.

Replace damaged or heavily corroded sections promptly to maintain system integrity.

Challenges and Limitations of Galvanized Steel Pipes

While galvanized steel pipes offer numerous advantages, they also have certain limitations:

Not Suitable for Certain Water Qualities: Highly acidic or alkaline water can corrode zinc over time.

Potential for Zinc Leaching: In some old systems, prolonged exposure to water may cause zinc to leach.

Weight: Heavier than plastic alternatives like PVC or PPR pipes.

Limited Use in High-Temperature Environments: Zinc coatings may degrade under extreme heat.

Conclusion

Galvanized steel pipes remain a cornerstone material in modern infrastructure and water supply systems. Their balance of strength, affordability, and corrosion resistance makes them a preferred choice for a wide range of industries, from construction and urban planning to agriculture and energy sectors.

When selecting galvanized steel pipes, it is essential to consider factors such as coating quality, size, application requirements, and supplier reliability. Guangqi, with its advanced manufacturing capabilities and commitment to quality, offers a comprehensive solution for businesses and infrastructure developers seeking long-lasting, high-performance piping systems.

In an era where infrastructure durability and sustainability are paramount, galvanized steel pipes continue to provide a reliable foundation for building the cities and water networks of tomorrow.

Common Uses of Galvanized Steel Pipes in Plumbing, Fencing, and Structural Work

www.gqsteelpipe.com

Foshan Nanhai Guangqi Steel Industry Co., Ltd.