In engineering, precision measurement tools are critical for ensuring accuracy, efficiency, and safety. Among the wide range of sensing instruments, dual-axis inclinometers stand out for their ability to measure angular tilt across two perpendicular planes. These devices are widely used in civil engineering, geotechnical monitoring, industrial automation, robotics, aerospace, and marine applications. This comprehensive guide will provide a deep dive into the working principles, applications, advantages, and practical considerations when integrating dual-axis inclinometers into engineering projects, while also highlighting the role of companies such as LINS, a high-tech enterprise specializing in inertial sensing technology and product integration.

Understanding Dual-Axis Inclinometers

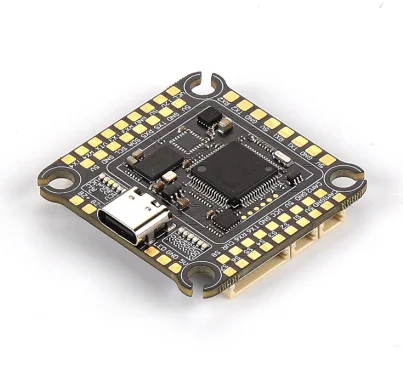

Dual-axis inclinometers are sensors designed to measure tilt angles relative to gravity in two axes, usually labeled as X and Y. These devices operate on the principle of detecting changes in gravitational acceleration using micro-electromechanical systems (MEMS) technology or electrolytic sensing mechanisms. The data output is typically in degrees or radians, which engineers can interpret to understand the precise angular position of structures or machines.

The key characteristic that makes dual-axis inclinometers particularly useful is their ability to provide simultaneous angular measurements along two axes, enabling accurate three-dimensional orientation monitoring when combined with other sensors.

Working Principles of Dual-Axis Inclinometers

The operation of a dual-axis inclinometer generally relies on the detection of acceleration due to gravity. MEMS-based inclinometers employ tiny capacitive sensors embedded on a silicon chip. As the sensor tilts, the position of a microstructure changes relative to gravity, altering capacitance values. These changes are converted into electronic signals and processed to deliver angle measurements.

Electrolytic inclinometers, by contrast, use a conductive fluid and electrodes to detect tilt. As the inclinometer tilts, the fluid shifts, changing electrical resistance or capacitance between electrodes. This change is interpreted as tilt data.

MEMS-based solutions are particularly popular due to their small size, robustness, and cost-effectiveness, making them suitable for modern industrial applications.

Advantages of Dual-Axis Inclinometers in Engineering

Dual-axis inclinometers offer several unique benefits that make them valuable across engineering disciplines:

High accuracy in angular measurement: Ideal for applications requiring precise monitoring.

Simultaneous two-axis tilt detection: Reduces the need for multiple sensors.

Compact and durable design: MEMS-based sensors are rugged and suitable for harsh environments.

Ease of integration: Digital and analog outputs make them adaptable to different control systems.

Low power consumption: Enhances portability in mobile or battery-powered systems.

These advantages make dual-axis inclinometers an indispensable choice for projects requiring continuous monitoring of orientation or tilt.

Applications in Civil and Structural Engineering

One of the most common uses of dual-axis inclinometers is in civil and structural engineering. They are employed in monitoring the stability and movement of bridges, tunnels, dams, and tall buildings. By measuring minute angular shifts, engineers can detect early signs of structural deformation and take preventive measures to avoid catastrophic failures.

Geotechnical engineers also rely on inclinometers to monitor ground movement in areas prone to landslides, earthquakes, or subsidence. In such cases, inclinometers are embedded in boreholes or installed on retaining walls to detect soil displacement and structural strain.

Role in Industrial Automation

Industrial automation requires precise monitoring and control of machinery orientation. Dual-axis inclinometers provide real-time tilt data that ensures robotic arms, cranes, and automated guided vehicles (AGVs) maintain correct alignment. This contributes to enhanced efficiency, safety, and repeatability in manufacturing processes.

For heavy machinery such as excavators and drilling rigs, inclinometers prevent unsafe operating angles by triggering automatic alarms or shutdown mechanisms. This makes them essential in construction and mining operations.

Applications in Aerospace and Marine Engineering

In aerospace engineering, dual-axis inclinometers play a crucial role in navigation, control, and safety systems. Aircraft use these sensors to monitor orientation during flight, assisting autopilot systems and improving stability. Spacecraft also benefit from inclinometers for precision positioning in microgravity environments.

Marine engineering employs inclinometers for monitoring ship tilt, roll, and pitch angles. Accurate tilt measurements enhance navigation, cargo stability, and operational safety in turbulent waters.

Enhancing Robotic Systems with Tilt Sensing

Robotics is a rapidly evolving field where precision and adaptability are vital. Dual-axis inclinometers provide orientation data that allows robots to maintain balance, execute complex movements, and interact with dynamic environments. For mobile robots, inclinometers improve navigation by detecting uneven terrain, while robotic arms benefit from precise angular alignment for tasks such as welding, assembly, or medical surgery.

Integration of Inclinometers in Modern Systems

Integrating dual-axis inclinometers into engineering systems requires careful consideration of several factors, including:

Mounting orientation: Placement affects the accuracy of readings.

Calibration: Regular calibration ensures long-term measurement reliability.

Environmental conditions: Protection against moisture, temperature variation, and vibration is critical.

Signal processing: Advanced filtering algorithms reduce noise and improve data accuracy.

Companies like LINS, with deep expertise in inertial sensing, provide not only advanced sensor hardware but also integrated solutions that simplify system design. Their focus on research, development, and integration ensures that clients benefit from reliable performance across diverse applications.

Choosing the Right Inclinometer for Your Project

Selecting the appropriate dual-axis inclinometer depends on project-specific requirements:

Measurement range: Some applications demand wide tilt angles, while others need high sensitivity within a narrow range.

Accuracy and resolution: High-precision applications such as aerospace or robotics demand finer resolution.

Environmental ruggedness: Outdoor and industrial use cases require durable, weather-resistant designs.

Output compatibility: The sensor should match the communication protocol of the control system.

Working with an experienced supplier such as LINS ensures that engineers receive tailored solutions optimized for their unique project needs.

Importance of Data Interpretation and Analysis

Collecting tilt data is only part of the process; interpreting and applying it is equally important. Engineering teams use inclinometer data for predictive maintenance, safety monitoring, and process optimization. Data analytics tools can detect trends, identify anomalies, and provide actionable insights.

In large infrastructure projects, continuous inclinometer monitoring systems can be integrated with cloud-based platforms, allowing remote access, automated alerts, and advanced reporting for stakeholders.

Conclusion

Dual-axis inclinometers are indispensable tools in modern engineering, offering precision, reliability, and versatility across multiple industries. From monitoring the stability of massive infrastructure to enhancing the accuracy of robotic systems, these sensors provide engineers with critical insights for safe and efficient operation. LINS provides advanced solutions that allow organizations to fully exploit the potential of inertial sensing technology and achieve superior performance in their projects.

This comprehensive guide underscores the importance of understanding, selecting, and integrating dual-axis inclinometers effectively. By mastering these aspects, engineers can ensure success across a wide range of applications where accuracy and reliability are paramount.

Practical Solutions Using Fiber Optic Gyroscopes in Smart Automation

www.lins-imu.com

Wuxi LINS Technology Co., Ltd.