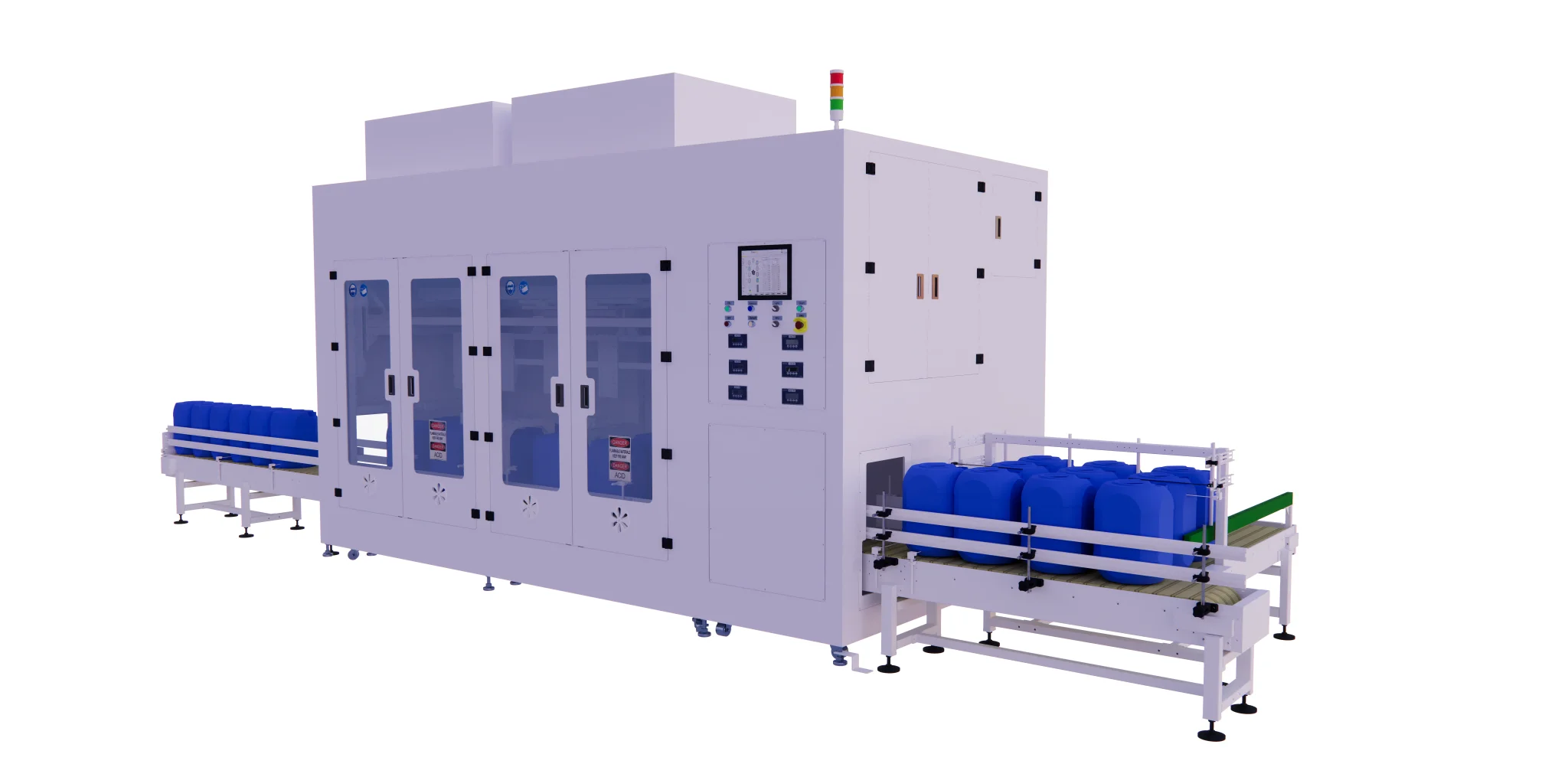

In modern manufacturing and laboratory operations, efficiency, precision, and reliability are key factors when selecting equipment. One crucial piece of machinery is the 4L–20L automatic filling line, which streamlines the process of filling liquids into containers ranging from 4 to 20 liters. Choosing the right filling line can significantly impact productivity, reduce waste, and ensure consistent quality. This article provides a comprehensive guide on selecting the ideal automatic filling line and highlights solutions offered by Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd., a leading developer and manufacturer of plastic equipment for laboratory and industrial applications.

1. Understand Your Production Requirements

Before selecting an automatic filling line, evaluate your specific production needs:

-

Volume Requirements: How many containers need to be filled per hour? High-volume operations may require faster and more automated systems.

-

Container Sizes: Ensure the machine can handle your current range of container sizes, particularly 4L–20L formats.

-

Liquid Viscosity and Properties: Consider whether your products are thin liquids, gels, or viscous solutions, as this impacts the choice of filling mechanism.

Xinruiwei provides customized solutions from prototype development to batch production, ensuring that filling lines are tailored to client-specific requirements.

2. Precision and Consistency

Accurate filling is essential to maintain product quality and minimize waste. Look for filling lines with:

-

Advanced sensors and flow control systems for precise volume measurement

-

Automated calibration features to adjust for different container types

-

Consistent fill rates to maintain smooth production and avoid overfilling or spillage

By utilizing European components, Xinruiwei ensures high precision and consistent performance in all its filling equipment.

3. Automation and Ease of Use

A high-quality automatic filling line should enhance productivity while minimizing operator intervention:

-

User-Friendly Interface: Intuitive controls reduce the learning curve for operators

-

Programmable Settings: Allows for quick adjustments for different products or container sizes

-

Integrated Conveyors and Packaging Systems: Streamlines workflow and reduces manual labor

Xinruiwei’s filling lines are designed with automation and operator efficiency in mind, delivering reliable performance and minimal downtime.

4. Durability and Maintenance

Industrial equipment must withstand continuous operation with minimal maintenance:

-

Robust Construction: Look for machines made from high-quality plastics and corrosion-resistant materials

-

Easy Access for Cleaning: Simplifies maintenance and ensures compliance with hygiene standards

-

Reliable Components: Using proven European parts enhances durability and reduces the risk of breakdowns

Xinruiwei’s machines are manufactured in China using top-tier European components, ensuring long-lasting reliability and consistent operation under demanding conditions.

5. Scalability and Integration

Your filling line should grow with your business:

-

Modular Design: Allows for easy upgrades or expansion of capacity

-

Compatibility with Other Systems: Ensure seamless integration with labeling, capping, and packaging equipment

-

Future-Proofing: Choose equipment that can adapt to new container types or production requirements

By offering end-to-end solutions, Xinruiwei supports clients from laboratory-scale prototyping to full-scale industrial production, providing flexible and scalable filling solutions.

Conclusion

Choosing the right 4L–20L automatic filling line requires careful consideration of production volume, container types, liquid properties, precision, automation, durability, and scalability. Investing in a high-quality filling line not only increases efficiency but also ensures consistent product quality and reduces operational costs.

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. offers expertly designed automatic filling lines tailored for laboratory and industrial applications. With a combination of Chinese manufacturing and European components, their machines deliver precision, reliability, and scalability, helping businesses streamline production while maintaining the highest quality standards.

Selecting the right filling line is an investment in operational efficiency, product consistency, and long-term business growth.

www.wafera.com

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd.