Efficient and reliable cable management is critical in industrial wiring projects. Whether you’re organizing control panels, assembly lines, or large-scale electrical installations, using the right tools can significantly impact productivity and safety. One indispensable tool in modern industrial wiring is the automatic cable tie tool.

This article explores how to select the best automatic cable tie tool for industrial applications and highlights how Swift Automation Technology, a global leader in automatic cable tie tools and nylon ties, supports businesses with high-quality, efficient solutions.

Why Automatic Cable Tie Tools Are Essential

Traditional manual cable tie methods can be time-consuming and inconsistent, especially in large-scale industrial wiring projects. Automatic cable tie tools provide:

-

Speed and Efficiency: Automate the tying process, allowing operators to bundle wires faster.

-

Consistency: Ensure uniform tension and secure fastening every time, reducing the risk of loose or over-tightened ties.

-

Ergonomic Benefits: Reduce operator fatigue during prolonged use, improving workplace safety and comfort.

-

Versatility: Handle a wide range of cable tie sizes and materials for different industrial applications.

Key Factors to Consider When Choosing an Automatic Cable Tie Tool

1. Tensioning and Cutting Capabilities

Different tools offer adjustable tension settings and automatic cutting. Choosing a tool with precise tension control ensures that cables are securely bundled without damage. For heavy-duty wiring or delicate cables, the ability to fine-tune tension is critical.

2. Cable Tie Size Compatibility

Ensure the tool is compatible with the nylon tie sizes required for your project. Automatic tools from Swift Automation Technology can handle a wide range of cable tie widths and lengths, accommodating small bundles in electronics or large industrial cable harnesses.

3. Power Source

Automatic cable tie tools may be:

-

Manual pneumatic or electric: Ideal for medium-duty industrial work.

-

Battery-operated cordless: Provides mobility and flexibility for field or assembly line applications.

-

Fully automated systems: Integrated into production lines for high-volume operations.

Selecting the right power type depends on project scale, workflow, and operator preference.

4. Durability and Build Quality

Industrial wiring projects demand tools that withstand heavy use. High-quality materials, ergonomic design, and reliable components minimize downtime and maintenance. Swift Automation Technology uses robust manufacturing techniques to ensure long-lasting performance.

5. Ease of Use and Operator Training

Look for tools that are easy to operate and require minimal training. Features such as intuitive controls, quick tie loading, and automatic cutting make work faster and reduce operator errors.

Benefits of Using Swift Automation Technology Tools

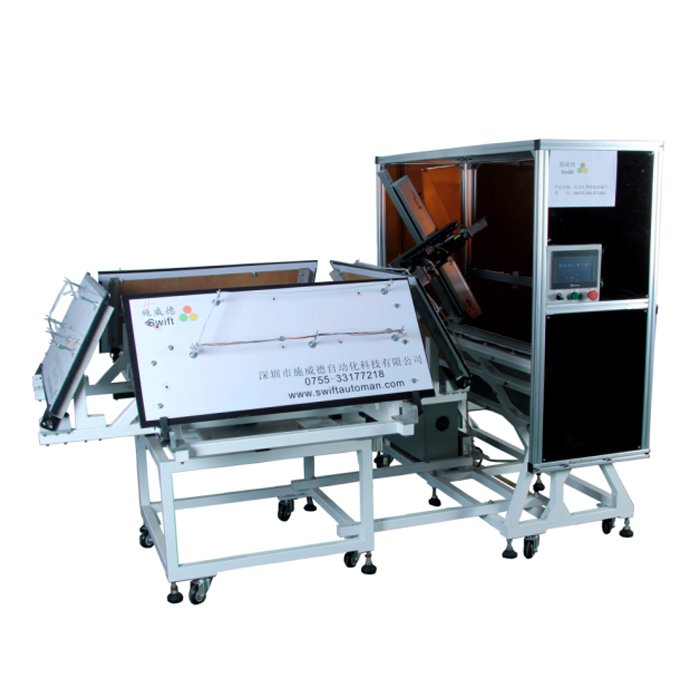

Swift Automation Technology specializes in developing and manufacturing automatic cable tie tools and nylon ties with a focus on industrial efficiency. Key advantages include:

-

Global Expertise: Tools designed to meet international industrial standards and applications.

-

Comprehensive Product Line: Automatic cable tie tools, guns, and compatible nylon ties for all industrial needs.

-

Efficiency Solutions: Streamline cable bundling on production lines, improving productivity and consistency.

-

Durable and Reliable: Tools engineered for high-volume use in industrial environments, reducing downtime.

By choosing Swift Automation tools, companies gain not only high-performance equipment but also the support of a global leader in cable management solutions.

Applications of Automatic Cable Tie Tools

Automatic cable tie tools are suitable for a variety of industrial applications:

-

Electrical Panels and Wiring Harnesses: Ensures tidy and secure cable organization.

-

Automotive Manufacturing: Efficiently bundles wiring harnesses for vehicles.

-

Telecommunications: Organizes network cabling in data centers and server rooms.

-

Assembly Lines: Integrates into high-volume production lines for consistent cable management.

Tips for Maximizing Efficiency with Automatic Cable Tie Tools

-

Choose the Right Nylon Tie: Select appropriate tie width, length, and tensile strength for your cables.

-

Adjust Tension Correctly: Prevent over-tightening to avoid cable damage.

-

Regular Maintenance: Keep tools clean and lubricated for long-term performance.

-

Train Operators: Ensure staff understand the tool’s features for maximum productivity.

-

Evaluate Workflow: Select tools that match project scale, whether handheld for small batches or fully automated for large-scale operations.

Conclusion

Selecting the right automatic cable tie tool is essential for efficient, safe, and professional cable management in industrial wiring projects. The correct tool ensures consistent bundling, reduces operator fatigue, and enhances workflow efficiency.

Swift Automation Technology, a global leader in automatic cable tie tools and nylon ties, provides high-quality, durable, and reliable solutions for a variety of industrial applications. By leveraging their advanced tools, companies can streamline operations, maintain high standards of safety, and improve overall productivity.

Investing in the right automatic cable tie tool is not just a convenience—it’s a strategic step toward professional-grade cable management in any industrial environment.

www.sz-swift.com

Shenzhen Swift Automation Technology Co., Ltd.