Choosing the right gasketed plate heat exchanger is a critical step in ensuring stable operation, energy efficiency, and long-term reliability in industrial processes. While gasketed plate heat exchangers are known for their high efficiency and flexibility, selecting an unsuitable model or configuration can lead to operational inefficiencies, frequent maintenance, or premature equipment failure.

This article outlines the key factors to consider when selecting a gasketed plate heat exchanger and explains how professional manufacturers like Kreat support customers throughout the selection and application process.

Understand Your Process Requirements First

Before selecting any heat exchanger, it is essential to fully understand the operating conditions of your process. A gasketed plate heat exchanger is not a one-size-fits-all solution, and proper selection begins with accurate process data.

Key parameters include:

-

Type of fluids on both hot and cold sides

-

Inlet and outlet temperatures

-

Flow rates

-

Operating pressure and temperature limits

-

Fouling tendency and fluid cleanliness

Accurate data allows engineers to determine the required heat transfer area and plate configuration, ensuring stable performance under real operating conditions.

Evaluate Fluid Compatibility and Plate Material

The choice of plate material directly affects corrosion resistance, service life, and overall system safety.

Stainless steel is commonly used for water-based systems, HVAC applications, and general industrial processes. For more aggressive media, such as certain chemicals or seawater, alternative materials like titanium may be required.

Kreat designs and manufactures plates using carefully selected materials based on fluid properties, ensuring compatibility with petroleum, chemical, food and beverage, power, metallurgy, shipbuilding, and HVAC applications.

Select the Appropriate Gasket Material

Gaskets play a critical role in sealing and fluid distribution within a gasketed plate heat exchanger. Selecting the correct gasket material is just as important as choosing the right plate.

Common considerations include:

-

Temperature range

-

Chemical compatibility

-

Pressure resistance

-

Hygiene requirements

Different gasket materials, such as NBR or EPDM, are selected based on these conditions. Poor gasket selection can result in leakage, reduced service life, or unexpected shutdowns.

As a professional manufacturer of heat exchanger gaskets, Kreat ensures that gasket materials match both process conditions and long-term operational expectations.

Determine the Required Heat Transfer Capacity

Heat transfer capacity is determined by the required thermal duty and the temperature difference between the fluids. Gasketed plate heat exchangers offer an advantage here due to their modular design.

If future capacity expansion is anticipated, additional plates can be added without replacing the entire unit. This flexibility makes gasketed plate heat exchangers particularly suitable for growing industrial systems or processes subject to seasonal variation.

Kreat supports customers with thermal calculations and application design, ensuring that each heat exchanger is sized accurately for both current and future requirements.

Consider Pressure Drop and Flow Arrangement

Pressure drop is a key factor that directly affects pump selection and operating costs. While high turbulence improves heat transfer, excessive pressure drop can increase energy consumption.

Flow arrangement—such as counter-current or parallel flow—also influences efficiency and system stability. A properly designed gasketed plate heat exchanger balances heat transfer performance with acceptable pressure drop limits.

Professional manufacturers use optimized plate patterns and channel designs to achieve this balance, ensuring stable and energy-efficient operation.

Assess Maintenance and Cleaning Requirements

One of the primary advantages of gasketed plate heat exchangers is their ease of maintenance. However, maintenance needs vary depending on the application.

Processes involving fouling fluids, suspended solids, or frequent temperature changes require heat exchangers that can be easily opened and cleaned. Detachable plate designs allow for mechanical or chemical cleaning and individual plate replacement.

Kreat not only manufactures detachable plate heat exchangers but also provides plate heat exchanger maintenance services, supporting customers throughout the entire equipment lifecycle.

Match the Heat Exchanger to Industry Standards

Different industries have different compliance requirements. For example:

-

Food and beverage processes may require hygienic designs

-

Chemical industries demand high corrosion resistance

-

Power and metallurgy applications require robust structures

Selecting a gasketed plate heat exchanger that aligns with industry standards ensures safe and compliant operation.

Kreat’s experience across multiple industries enables it to design solutions that meet both technical and regulatory expectations.

Choose a Manufacturer with Engineering Support

Selecting the right heat exchanger is not just about the product itself—it is also about the manufacturer’s technical capability and service support.

Kreat is a comprehensive enterprise integrating product research and development, application design, manufacturing, sales, and technical services. This integrated approach allows Kreat to support customers from initial selection to installation, operation, and long-term maintenance.

The company is located in Xuxiake Town, Wuxi City, Jiangsu Province, offering excellent logistical advantages with convenient access to Shanghai, Nanjing, Wuxi, and the Yangtze River. This strategic location supports efficient delivery and responsive customer service.

Explore Proven Product Designs

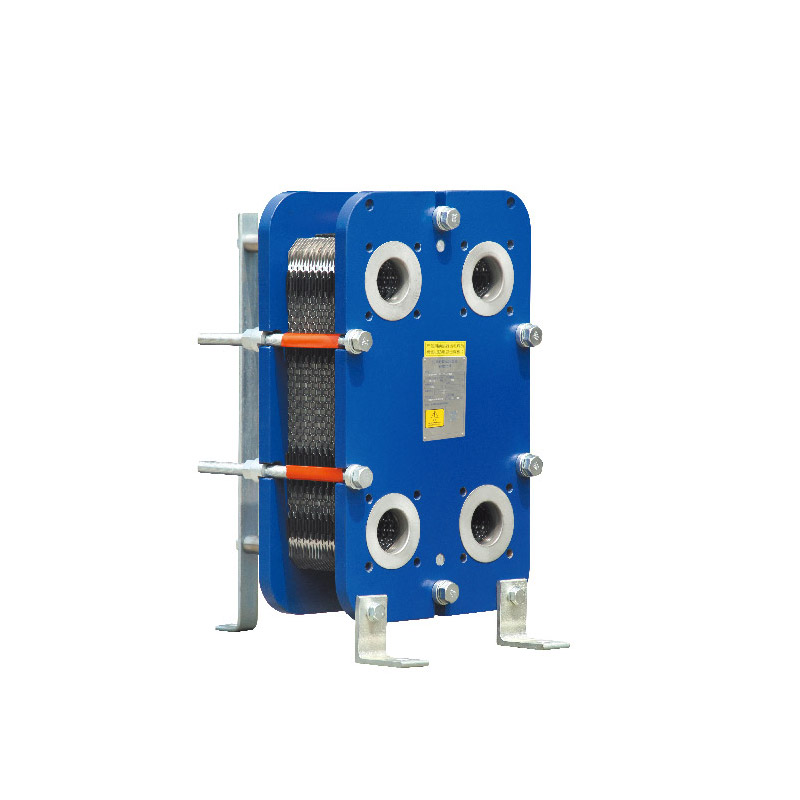

Kreat currently produces numerous models of detachable and brazed plate heat exchangers. Each product is designed with precision manufacturing and strict quality control to meet demanding industrial requirements.

Detailed product descriptions and technical features can be found at:

https://www.kreat-phe-os.com/Detachable-plate-heat-exchanger

These designs reflect Kreat’s commitment to stable performance, ease of maintenance, and long-term reliability.

Quality as the Foundation of Selection

“Quality First, Integrity Foremost” is the guiding principle behind all Kreat operations. From material selection and plate pressing to gasket molding and final assembly, every production step is strictly controlled.

High-quality products are essential for competing in international markets and for delivering long-term value to customers. By focusing on precision manufacturing and continuous improvement, Kreat ensures that its gasketed plate heat exchangers consistently perform under real industrial conditions.

Conclusion

Selecting the right gasketed plate heat exchanger requires a clear understanding of process conditions, material compatibility, maintenance needs, and long-term operational goals. A well-selected unit not only improves heat transfer efficiency but also reduces downtime and operating costs.

With strong engineering expertise, strict quality control, and comprehensive service capabilities, Kreat supports customers in making informed decisions and achieving reliable, efficient heat transfer across a wide range of industrial applications.

www.kreat-phe-os.com

Kreat