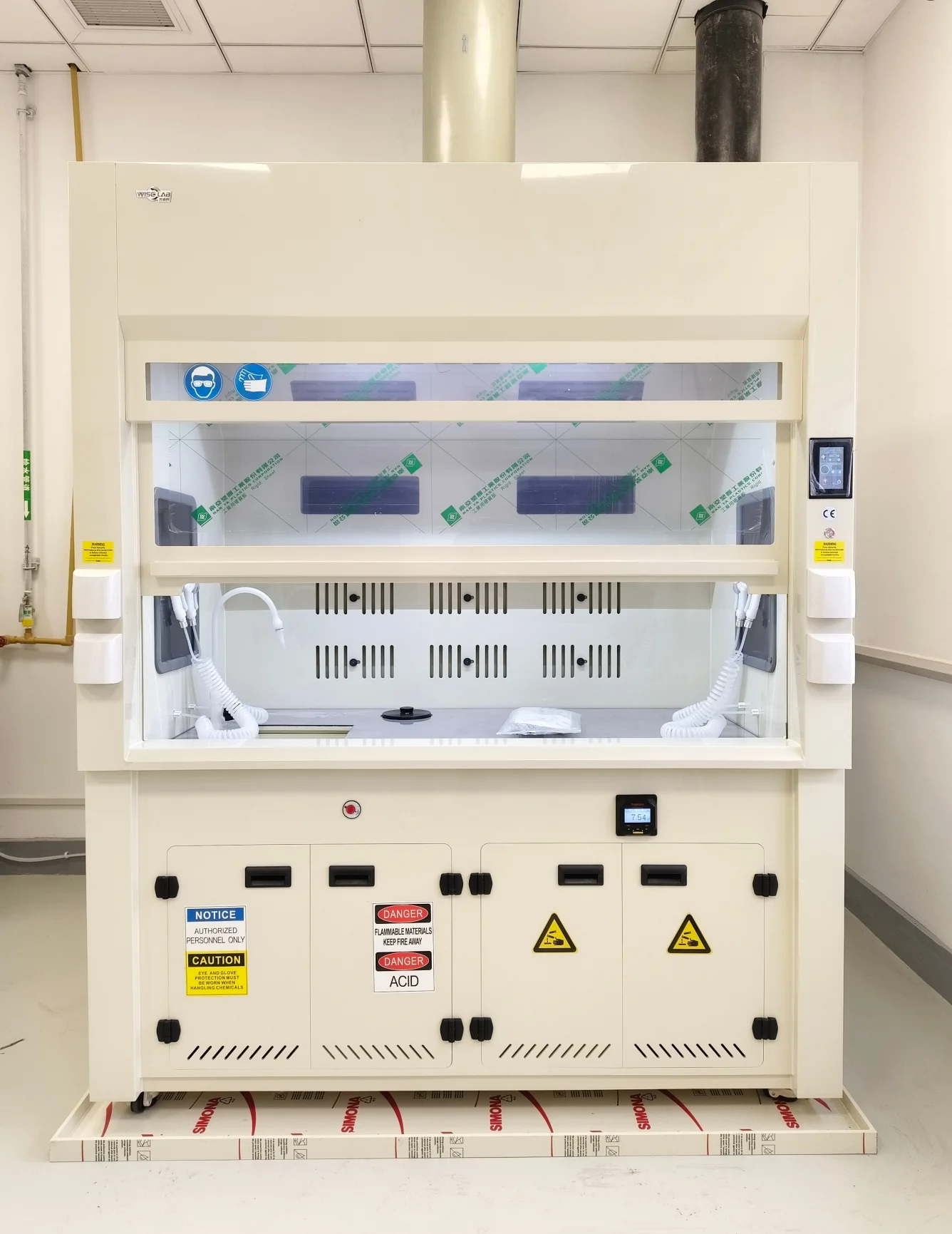

In semiconductor, chemical, and wet-process labs, a fume hood isn’t just “a box with airflow.” It’s a safety barrier, a contamination control tool, and often the workstation where your team spends hours handling acids, alkalis, solvents, and DI water (DIW). When the process includes spray washing or frequent rinsing, the hood also has to manage liquid control—without creating corrosion points, leaks, or static-related risks.

That’s where a PVC anti-static spray washing fume hood becomes a practical choice. Built with FM4910 fire-resistant PVC board and an anti-static tabletop treatment, it’s designed for aggressive chemical environments while keeping day-to-day operation straightforward for technicians.

Why “PVC anti-static” matters in wet chemical work

Wet benches and spray washing applications create a unique combination of risks:

-

Chemical exposure: strong acids/alkalis can corrode metal parts and damage coatings over time.

-

Water and droplets: spray washing increases splash, mist, and the chance of pooling.

-

Static control needs: certain cleanroom or sensitive environments require control of surface resistivity to reduce electrostatic risks on the work area.

This hood addresses that with a structure made from FM4910 fire-resistant PVC board and a tabletop treated for anti-static performance. The provided surface resistivity range—10^5 to 10^9 ohms—is a practical span for reducing static buildup on the work surface while still maintaining robust, chemical-resistant construction.

When perchloric acid is involved: the hazard isn’t only “corrosion”

If your workflow includes perchloric acid, the risk profile changes. Perchloric acid vapors can form crystalline deposits inside ducting, especially on duct walls, elbows, reducers, and areas ahead of fans. Those crystals are a major safety concern because perchlorate residues can carry explosion risk, particularly when they contact organic materials.

For this reason, a perchloric-acid-capable hood is not just “spray washing ready.” It needs active prevention against crystal buildup in the exhaust path.

A proven approach is a specialized configuration that integrates three core functions:

-

Back spray washing (duct spray) to keep the exhaust path clean

-

FM4910 fire-rated materials for cleanroom fire safety and improved risk control

-

Active perchloric-acid protection logic that prevents crystal accumulation rather than reacting after it happens

If perchloric acid is on your chemical list, plan the hood as a system (hood body + ducting + fan interface + wash/neutralization + waste handling), not a standalone cabinet.

Material selection: FM4910 fire-resistant PVC board

If you’ve used standard materials in chemical areas, you’ve probably seen the same long-term issues: corrosion around fasteners, bubbling paint, swelling panels, or leaks from degraded joints. Using a fire-resistant PVC board helps avoid many of those failure modes because PVC is inherently suited for wet and corrosive environments when properly specified.

In real operations, this usually means:

-

less concern about rust and coating breakdown

-

easier cleaning after chemical spills

-

more stable performance in humid, rinse-heavy workflows

For cleanroom projects that must meet higher fire-safety expectations, specifying FM4910-qualified PVC provides an added layer of confidence in material selection.

Sliding door design: smooth operation and stable positioning

In a production environment, a hood sash that sticks, drops, or won’t hold position isn’t a minor annoyance—it becomes a safety issue and slows down work.

This hood uses a top and bottom balanced sliding door, which supports:

-

smoother up/down movement

-

the ability to fix the door at any position, so operators can set the opening based on task and airflow needs

The window panel is specified as 6T transparent PVC acid-resistant board, giving chemical resistance while maintaining visibility into the work zone—important during spray washing and inspection steps.

Spray washing-ready work surface: access + drainage control

A spray washing hood must handle two things well: liquid management and maintenance access.

Activity drip working surface

The work surface is made of FM4910 fireproof PVC board, 10 mm thickness, with load-bearing capacity above 80 kg—useful if your process includes heavier fixtures, containers, or tooling.

What makes it especially practical for wet processes is the surface design:

-

openings on the surface (hole diameter 8 mm, spacing 50 mm)

-

openings can be accessed anytime for inspection and bottom maintenance

-

a leak-proof inner groove under the surface

-

inclined design to help guide droplets toward discharge and piping

In plain terms: it’s designed to reduce standing liquid, channel runoff in a controlled way, and make it easier to inspect and maintain the underside without disassembling half the hood.

Back spray washing system for duct safety (recommended for high-risk acids)

For general wet benches, surface spray and sink drainage may be enough. But for high-risk acids—especially perchloric acid—consider adding duct-focused spray washing.

Why back spray washing matters

Back spray washing helps prevent dangerous residues by washing the duct interior where deposits tend to form. The goal is to keep problem areas—like duct bends, diameter transitions, and the region before the fan—from becoming crystal collection points.

Closed-loop neutralization: the “right” way to spray for perchloric acid

For perchloric acid protection, the spray washing system should be designed as a closed-loop acid–base neutralization system. Plain water spray may dilute residues, but it typically does not address the problem at the root, and in some scenarios it can create unpredictable localized reactions.

A practical closed-loop concept includes:

-

Spray nozzle layout: dedicated nozzles on duct inner walls (especially elbows/reducers) and in front of the fan

-

Neutralization circulation unit: neutralization liquid tank (e.g., dilute alkaline solution), corrosion-resistant circulation pump, filtration, and pH monitoring

-

Operating logic: dual spray stages can be used; once activated, neutralizing liquid is sprayed evenly on duct walls to dissolve and neutralize residues; wastewater is collected, filtered, pH-adjusted, and recirculated; each unit can include automatic alkaline dosing for pH control

Key engineering details buyers should insist on

These details are where “looks good on paper” becomes “safe in real operation”:

-

Wetted component materials: all parts in contact with liquid (pump, piping, nozzles) should use perchloric-acid-capable materials such as PTFE or high-purity PP

-

Leak prevention: special sealing and guided drainage at cabinet/duct connections, plus a leak detection alarm

-

Duct slope: slight duct incline to ensure spray liquid fully returns to collection—no trapped liquid, no stagnant pockets

Integrated sink: built for DIW and harsh chemistry

For many wet-lab workflows, the sink becomes the real workhorse—rinsing parts, washing tools, draining DIW, and handling chemical residues.

This hood includes a sink on the right side of the workbench with dimensions:

-

W300 × D250 × H100

It also includes:

-

a 20 mm diameter drain tube located centrally

-

a pneumatic switch for the drain (open/close anytime to release water)

-

two gooseneck faucets above the sink

A key operational point: the sink is described as capable of holding DIW and strong acids/alkalis, with attention to joint corrosion resistance at the bottom connection—exactly where many systems fail over time.

Drain system: resistance to strong acids and alkalis

Drainage is often the hidden weak point in wet benches. Even if the main cabinet is chemical resistant, a poor drain tube choice will show problems quickly—softening, cracking, leakage, or failure at joints.

Here, the drain tubes are specified to withstand strong acids and alkalis, which is essential for:

-

reducing leak risk under the bench

-

improving long-term stability during frequent rinsing and discharge

-

supporting safer maintenance routines

Faucet and piping: PVDF / PFA for chemical reliability

The hood includes a PVDF or PFA gooseneck faucet configuration, with a 3/8-NPT pipe diameter used above one sink, and PFA material specified for the pipeline.

Why this matters in real projects:

-

PVDF and PFA are commonly selected for chemical resistance in demanding wet processes

-

choosing appropriate wetted materials helps reduce contamination and corrosion

-

it supports stable performance when users switch between DIW and aggressive chemicals

Choosing the right spray approach: quick comparison

To make decisions easier, here’s a practical comparison of two common spray strategies:

| Feature | Water / basic spray system | Closed-loop neutralization spray system |

|---|---|---|

| Primary goal | General cleaning, rinsing residues | Prevent perchloric acid crystal buildup; reduce explosion risk |

| Working liquid | Water | Formulated dilute alkaline neutralization liquid |

| Safety level | Moderate (rinse-focused) | Higher (neutralization-focused, proactive risk reduction) |

| Best fit | Standard wet chemistry tasks | Perchloric acid, fuming sulfuric acid, and other high-risk crystallizing acids |

| System complexity | Lower | Higher (circulation, filtration, pH monitoring, auto dosing) |

Where this hood fits best

Based on the material set and the spray washing + drainage focus, this hood is a strong fit for:

-

semiconductor wet process support areas

-

chemical distribution and chemical handling labs

www.topairsys.com

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd.About Author