In the polyurethane (PU) industry, precision, efficiency, and quality are the pillars of a successful production line. Whether manufacturing automotive components, insulation panels, or flexible foam products, the mixing head plays a central role in determining the final product’s consistency and performance. Among the different types of mixing heads, the T-shaped mixing head stands out for its superior control, compact structure, and high-performance mixing.

As one of the world’s leading manufacturers of polyurethane production and processing equipment, Haifeng has developed advanced T-shaped mixing heads that are engineered to meet the rigorous demands of modern PU manufacturing. In this article, we take a deep dive into the standout features that make T-shaped mixing heads essential for high-efficiency polyurethane pouring systems.

1. Exceptional Mixing Performance

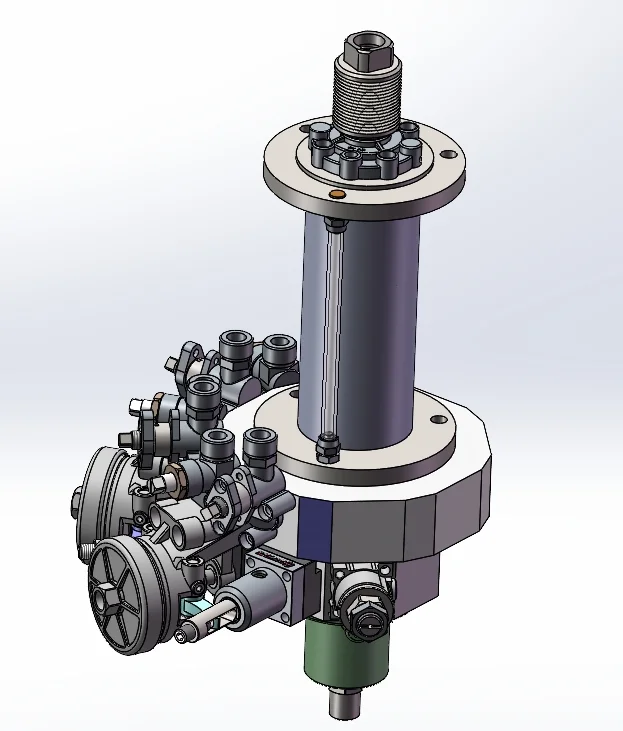

T-shaped mixing heads are designed for high-pressure impingement mixing, where the polyol and isocyanate components collide at high velocity in a small mixing chamber. This method creates a highly uniform blend, ensuring excellent foam quality with consistent cell structure, density, and physical properties.

Haifeng’s T-shaped mixing heads are optimized using advanced flow simulation technology to ensure complete and rapid mixing, minimizing the risk of defects and reducing material waste.

2. Compact and Efficient Design

The T-configuration is not only functional but space-saving. With minimal footprint and easy integration, it is ideal for fully automated PU lines, where space and accessibility are crucial. The inline horizontal flow path also improves precision in robotic and motion-controlled pouring systems, increasing production accuracy and repeatability.

Haifeng’s mixing heads are particularly suited for automated workstations used in sectors like automotive seating, mattress production, footwear, and appliance insulation.

3. Durability and Long Service Life

Industrial environments demand robust equipment. Haifeng uses high-strength alloys and corrosion-resistant materials to manufacture the core components of its T-shaped mixing heads. Key parts like the mixing chamber and injectors are designed for extended life under high pressure and repeated use.

Moreover, Haifeng’s mixing heads incorporate self-cleaning systems and easy-to-replace modular components, reducing maintenance time and operating costs.

4. Precision Flow and Ratio Control

Accurate control of the mixing ratio is critical in PU production. Haifeng’s mixing heads are equipped with high-precision servo or pneumatic injectors, allowing exact adjustment of component flow rates. This ensures consistent performance for different formulations—whether flexible, rigid, high-resilience, or viscoelastic foams.

This feature also allows manufacturers to quickly switch between formulations, improving flexibility and production uptime.

5. Adaptability Across Applications

T-shaped mixing heads are highly versatile, supporting a wide range of PU applications—from car seats and dashboards to cold storage insulation and specialty foams. Haifeng offers a variety of models to handle different output volumes, viscosities, and reactivity levels, giving customers a custom solution for virtually any production need.

Their engineering team works closely with clients to optimize head selection and layout for specific projects, ensuring a perfect match between the equipment and the application.

6. Smart Monitoring and Safety Features

Modern production demands real-time data and built-in safety. Haifeng’s T-shaped mixing heads feature digital monitoring systems for pressure, temperature, and flow rate. Advanced safety interlocks and alarms help prevent overpressure, blockages, or formulation errors, ensuring safe and efficient operation even in 24/7 industrial settings.

This proactive approach to safety and diagnostics reduces downtime and enhances operator confidence.

7. Energy-Efficient Operation

In today’s competitive and environmentally conscious market, energy efficiency is a key differentiator. Haifeng’s T-shaped mixing heads are engineered for low energy consumption without compromising performance. Efficient component mixing and smart pump control lead to lower waste, reduced chemical use, and a smaller environmental footprint.

Conclusion

The T-shaped mixing head is a small but powerful component that can make or break the quality and efficiency of your polyurethane production. Its compact design, reliable performance, and adaptability make it an essential asset in modern factories.

Haifeng, as a global leader in polyurethane production and processing systems, offers a full range of T-shaped mixing heads designed to meet the evolving needs of manufacturers across industries. Backed by decades of innovation, world-class engineering, and responsive customer support, Haifeng continues to help businesses improve quality, reduce costs, and stay ahead of the competition.

If you're looking to upgrade your PU pouring technology or need expert advice on selecting the right mixing solution, Haifeng is your trusted partner for long-term success.

Working Principle of Polyurethane Pouring Machine

Haifeng to Showcase at the 33rd INT'L Exhibition on Shoes and Leather Industry – Guangzhou

www.haifeng-automation.cn

Haifeng