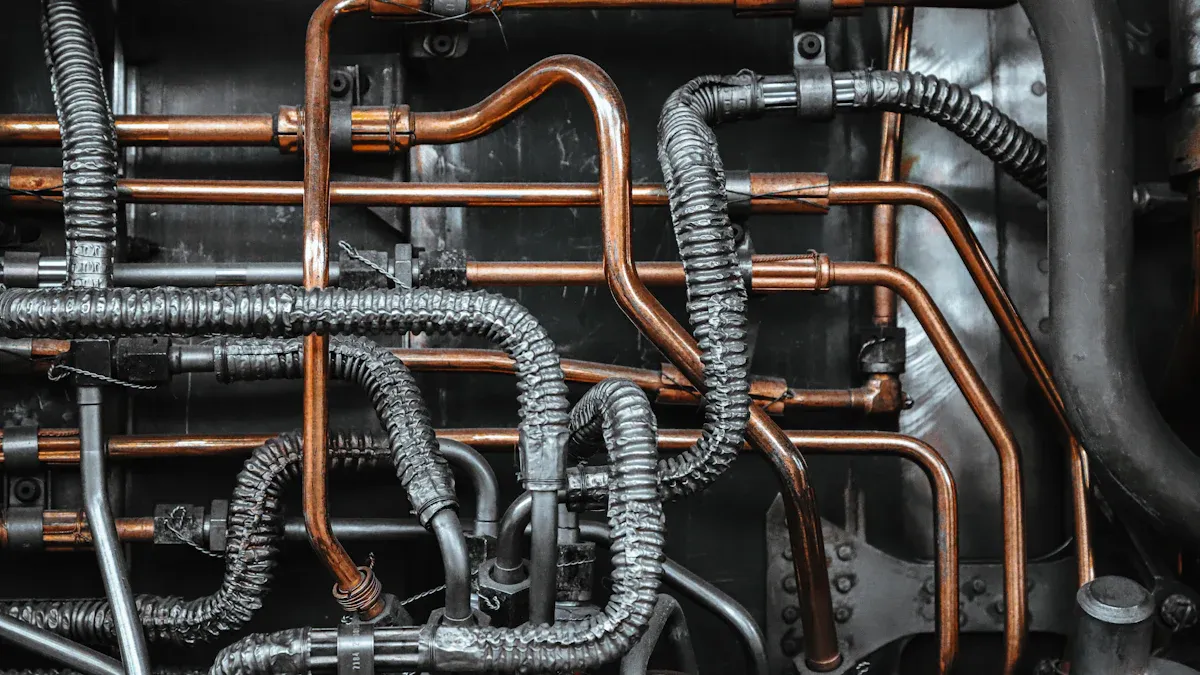

Engineers often see leaks in hydraulic systems when tubes break under high pressure. The carbon steel seamless tube helps fix this by giving strong and safe connections. It keeps pressurized fluids inside without trouble. The EN 10305-4 E355 standard makes sure each tube is good for hydraulic use. These tubes do not rust or wear out easily. They also handle heat well and are easy to shape. Many industries pick carbon steel seamless tube because it saves money, lasts long, and helps systems work safely and well.

Key Takeaways

-

Carbon steel seamless tubes give strong, tight connections. They are great for high-pressure hydraulic systems. These tubes do not rust easily. They can handle heat well. They are simple to bend and shape. This makes them last long and saves money. Standards like EN 10305-4 E355 make sure tubes are strong and high quality. Good installation is important. Checking and caring for the tubes often keeps systems safe. It also helps tubes last longer. Picking the right tube grade, size, and connection is important. This helps hydraulic systems work well and not break down.

Suitability for Hydraulics

Key Benefits

Carbon steel seamless tube is very strong and tough. This makes it great for hydraulic systems. Engineers use seamless pipe when pressure is high. There are no welds or joints in seamless pipe. Weak spots do not form because of this. The design helps the pipe last longer and work better. Seamless pipe does not bend or break easily, even with heavy loads. The tube is thick and has exact measurements. This helps it work well in hard jobs.

Seamless pipe does not rust easily. Special coatings like galvanization or epoxy help it last longer. These coatings protect the pipe in rough places. The pipe can bend without breaking. This helps when making tricky hydraulic systems. It is easier to install and take care of seamless pipe. There are no weld seams that need extra work.

Tip: Using carbon steel seamless pipe in hydraulic systems helps stop leaks and keeps things safe.

Key advantages include:

-

Durability means it lasts a long time.

-

Corrosion resistance keeps it safe from water and chemicals.

-

Flexibility helps make custom system designs.

-

Easy installation and care save time and work.

Common Applications

Many industries use seamless pipe in hydraulic systems. Car makers use carbon steel seamless pipe in power steering and brake lines. Construction workers use seamless pipe in big machines like excavators and cranes. Factories use seamless pipe for hydraulic presses and pumps. Farmers use seamless pipe to move fluids in their equipment. Industrial machines use seamless pipe for valves and piping.

|

Steel Grade / Type |

Pressure Level |

Typical Industry Applications |

|---|---|---|

|

#10 and #20 carbon steel |

General to medium pressure |

Small hydraulic equipment, machine tool hydraulic systems |

|

#45 carbon steel |

Medium to high pressure |

Engineering machinery hydraulic systems |

|

Alloy steels (15CrMo, 12Cr1MoV) |

High temperature and pressure |

Large industrial equipment (e.g., metallurgical) |

|

Medium carbon alloy steels (35CrMo, 42CrMo) |

High strength and toughness |

Heavy machinery hydraulic systems |

Seamless pipe is important in oil and gas, power plants, and chemical factories. These places need pipes that work well under high pressure and heat. Carbon steel seamless tube gives the strength and safety needed for these tough jobs.

Carbon Steel Seamless Tube Overview

Manufacturing Process

Manufacturers make seamless pipe for hydraulic systems with care. They pick solid steel billets to start. Workers heat the billets in a furnace until they are soft. The temperature is about 1200°C. Next, they use rotary tools to make a hole in the hot billet. This forms a hollow shell. Heavy rollers stretch and shape the shell. A mandrel inside the tube keeps the inside smooth. It also makes sure the wall is even. The tube cools slowly so it does not get stressed. Machines straighten the tube if it bends. After this, workers polish the tube’s surface. They may add coatings or heat treatments to make it better. Quality control teams check the tube for strength and size. They also look for any surface problems. They use special tests for this. At the end, they cut the pipe to the right length. Then they get it ready to ship.

After making the tube, many products get a phosphating treatment. This puts a protective layer on the inside and outside. The layer stops rust and helps paint stick. This makes the tube good for hydraulic systems. These systems need high corrosion resistance and smooth surfaces.

Seamless vs Welded Pipe

Seamless pipe and welded pipe have different uses in hydraulic systems. Seamless pipe is strong and reliable. It does not have weld seams. This means there are no weak spots. Welded pipe is made by bending and joining steel plates. It has a seam that can be weaker and not hold as much pressure.

|

Factor |

Seamless Pipes |

Welded Pipes |

|---|---|---|

|

Cost |

Higher due to complex manufacturing |

More cost-effective |

|

Strength |

Higher strength, no weld seam weak points |

Slightly lower strength; weld seam is a weak point |

|

Size |

Limited to smaller diameters (up to ~24 inches) |

Available in larger diameters |

|

Environmental Suitability |

Ideal for harsh, corrosive, and high-pressure environments |

Suitable for moderate conditions |

|

Maintenance |

Requires less frequent maintenance |

Requires periodic inspection of weld seams |

|

Production Time |

Longer lead times |

Faster production |

|

Application |

High-pressure, critical, and safety-sensitive uses |

General-purpose, low to moderate pressure uses |

Seamless pipe has a smooth inside. This helps fluids flow without losing pressure. It also makes the system work better. That is why carbon steel seamless tube is best for high-pressure and important hydraulic jobs.