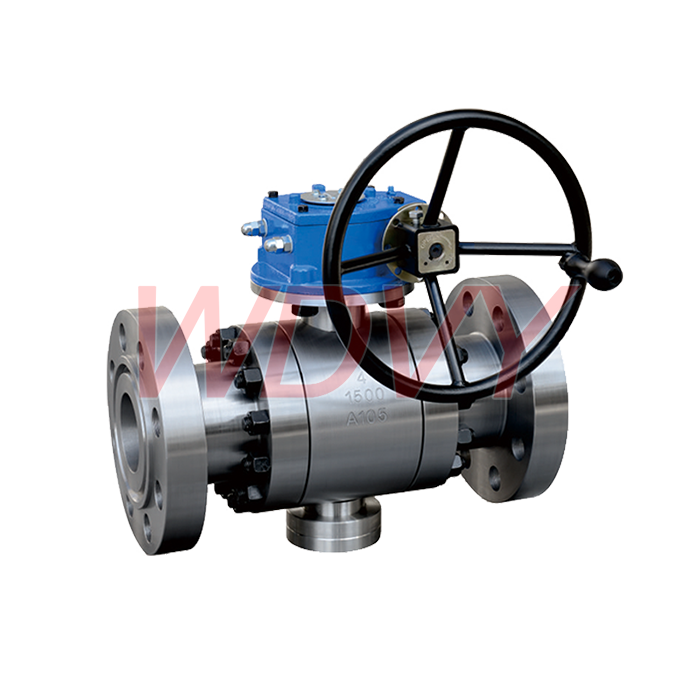

In demanding industrial environments such as oil & gas, petrochemical, power generation, and water treatment, trunnion mounted ball valves are the go-to choice for precise flow control and secure shut-off. Designed for high pressure and large-diameter applications, these valves offer exceptional durability and performance. However, selecting the right trunnion mounted ball valve involves understanding critical factors such as materials, sizing, and pressure ratings.

As a professional industrial valve manufacturer, Zhejiang Wandong Valve Co., Ltd. specializes in producing high-quality valves through a vertically integrated production system. With dedicated workshops for ball valves, large-diameter gate valves, special stainless steel valves, and a multi-functional facility producing globe valves, check valves, and Y-strainers, Wandong delivers tailored solutions for diverse industrial applications.

Here’s a comprehensive guide to help you choose the right trunnion mounted ball valve for your specific needs.

1. Understand the Application Requirements

Before selecting a valve, define your operational conditions:

-

Medium type (oil, gas, water, corrosive chemicals)

-

Flow rate

-

Operating pressure and temperature

-

Frequency of use (on/off cycles)

Trunnion mounted ball valves are typically used in high-pressure pipelines and large-bore systems, where bubble-tight shutoff and long service life are essential. Zhejiang Wandong Valve’s precision engineering ensures reliable performance even in harsh conditions.

2. Choose the Right Material for Corrosion and Pressure Resistance

Material selection affects valve longevity, compatibility, and cost. Common materials include:

-

Carbon Steel (e.g., A105): Ideal for general-purpose oil and gas pipelines

-

Stainless Steel (e.g., SS316/SS304): Excellent for corrosive environments and high temperatures

-

Duplex or Super Duplex Stainless Steel: Used in offshore and chemically aggressive environments

-

Low-Temperature Carbon Steel: Suitable for cryogenic applications

Wandong Valve offers a full range of special stainless steel options, produced in their dedicated workshop to meet the highest international standards.

3. Determine the Correct Valve Size

Valve size must align with pipeline dimensions and required flow rates. Trunnion mounted ball valves are especially suitable for:

-

Medium to large diameter applications (typically 2" to 48" or larger)

-

Systems that need low-torque operation and stable sealing across large volumes

Zhejiang Wandong specializes in large-diameter ball and gate valves, enabling customers to source reliable, high-precision valves for complex pipeline systems.

4. Match the Valve with the Appropriate Pressure Rating

Trunnion mounted ball valves are built for high-pressure performance. Common pressure ratings include:

-

Class 150 – 2500 (ANSI)

-

PN10 – PN420 (DIN/ISO)

Consider the maximum system pressure, including surges and transient spikes. Wandong's valves are rigorously tested to comply with global standards, ensuring safety and durability under extreme pressure conditions.

5. Look for Industry Certifications and Testing Standards

Quality assurance is vital for critical infrastructure. Make sure your valves are:

-

Manufactured according to API, ANSI, ISO, DIN standards

-

Tested for shell pressure, seat leakage, and fire safety (API 607/API 6FA)

-

Traceable with material certificates and inspection reports

Wandong Valve ensures all products undergo strict quality control in its vertically integrated production facilities, supported by comprehensive documentation and after-sales support.

6. Consider Special Features and Custom Options

Depending on the use case, you may need:

-

Double block and bleed (DBB) capability

-

Anti-blowout stem design

-

Emergency seat injection system

-

Fire-safe construction

-

Extended stem for buried service

With multiple workshops and deep engineering expertise, Zhejiang Wandong Valve Co., Ltd. can provide customized valve configurations to match any application requirement.

Final Thoughts

Choosing the right trunnion mounted ball valve requires careful consideration of material compatibility, pressure and temperature ratings, and size. By partnering with an experienced manufacturer like Zhejiang Wandong Valve Co., Ltd., you gain access to a complete solution—from material selection and design to production and testing.

With a vertically integrated structure and specialized workshops for each valve category, Wandong ensures quality, flexibility, and timely delivery for industrial clients around the globe.

www.wdfmvalves.com

Zhejiang Wandong Valve Co., Ltd.