In modern electrical and industrial control systems, wiring efficiency has become a critical factor in overall system reliability, safety, and scalability. As control panels grow more compact and functional requirements increase, traditional single-level wiring solutions often struggle to keep up. This is where the double-level terminal block has gained widespread adoption across industries such as automation, machinery manufacturing, energy, and building systems.

Understanding the Basics of a Double-Level Terminal Block

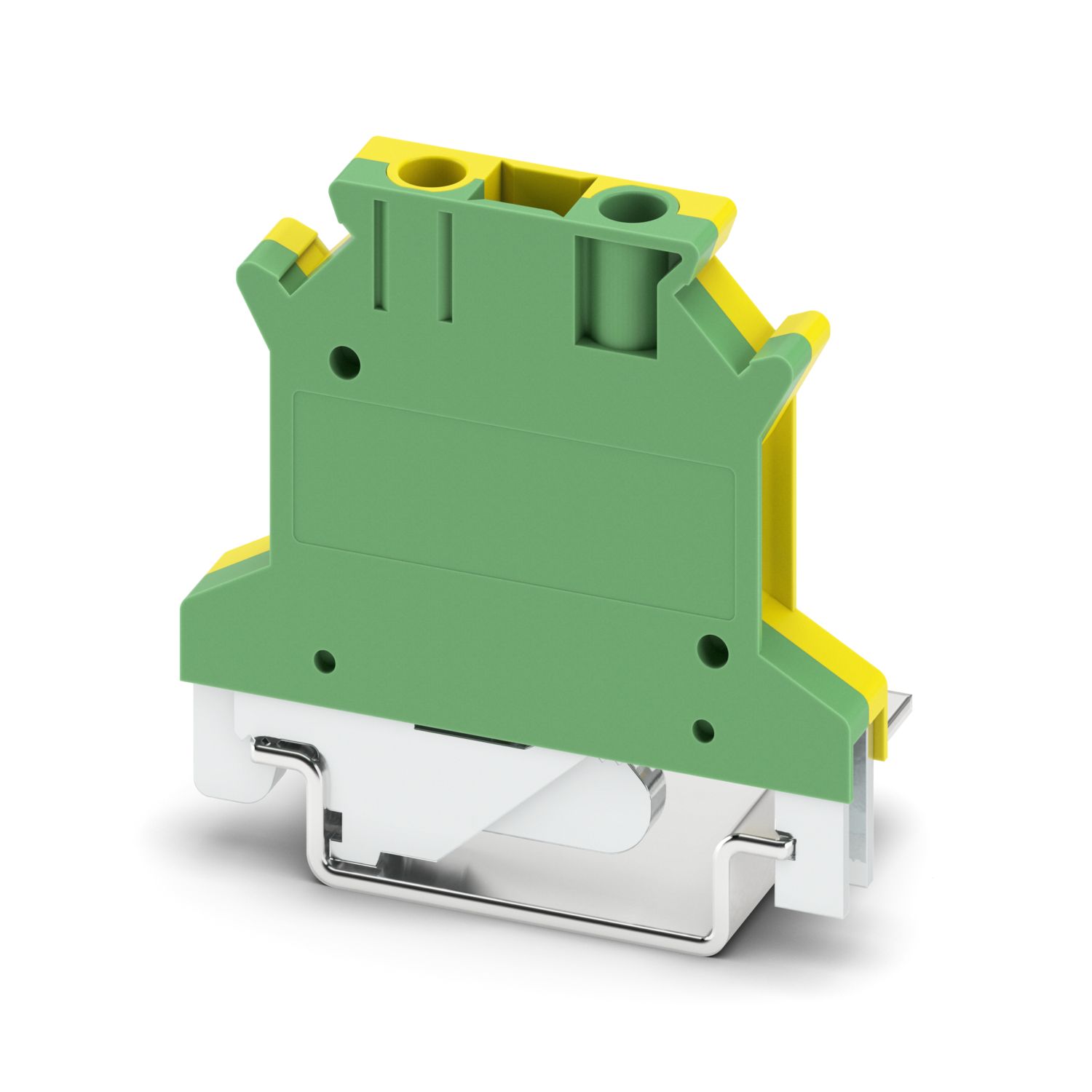

A double-level terminal block is a wiring component designed with two independent wiring levels stacked vertically within a single terminal block housing. Each level functions as a separate electrical connection point, allowing two circuits to be wired in the same footprint where traditionally only one circuit could be placed.

Unlike standard single-level terminal blocks, which require additional rail space for every circuit, double-level designs effectively double wiring capacity without expanding the panel layout. This structural advantage makes them especially useful in control cabinets where DIN rail space is limited.

Manufacturers like Linhao design double-level terminal blocks to meet industrial standards while maintaining mechanical stability, insulation integrity, and consistent electrical performance.

Why Wiring Efficiency Matters in Industrial Panels

Wiring efficiency is not just about saving space. It affects multiple aspects of system performance and lifecycle cost, including:

-

Panel size and material cost

-

Installation time and labor accuracy

-

Cable routing clarity

-

Heat dissipation and airflow

-

Troubleshooting and maintenance efficiency

Poorly planned wiring can lead to crowded panels, higher risk of wiring errors, and longer downtime during servicing. Double-level terminal blocks address many of these challenges by enabling cleaner, more organized layouts.

How Double-Level Terminal Blocks Improve Wiring Efficiency

1. Higher Connection Density Without Compromising Organization

One of the most significant benefits of double-level terminal blocks is their ability to increase wiring density while maintaining clear separation between circuits. Each level is electrically isolated, allowing signal, control, or power lines to coexist in a structured manner.

For example, in automation systems, upper levels may be used for signal wiring while lower levels handle common or return lines. This structured layering improves readability and reduces wiring confusion during installation and inspection.

2. Reduced DIN Rail Usage and Compact Panel Design

By stacking two circuits into one terminal block position, double-level terminal blocks significantly reduce DIN rail length requirements. This enables more compact control cabinets or allows designers to integrate additional components without increasing enclosure size.

For OEMs and panel builders, this translates into lower enclosure costs and more flexible panel layouts—an increasingly important factor as equipment becomes smaller and more integrated.

3. Improved Wiring Clarity and Traceability

Despite higher density, well-designed double-level terminal blocks maintain clear marking surfaces for both levels. This ensures that wire identification remains visible and compliant with electrical standards.

Clear labeling reduces installation errors and simplifies troubleshooting. Technicians can quickly identify circuits without dismantling adjacent wiring, saving time during maintenance or upgrades.

4. Faster Installation and Reduced Labor Time

When wiring layouts are optimized, installation becomes faster and more predictable. Double-level terminal blocks allow electricians to complete more connections within the same workspace, reducing repetitive rail mounting and alignment tasks.

In large-scale projects, these time savings accumulate, improving overall project efficiency and delivery schedules.

Typical Applications of Double-Level Terminal Blocks

Double-level terminal blocks are widely used across multiple sectors, including:

-

Industrial automation control cabinets

-

PLC and I/O systems

-

Machinery and equipment wiring

-

Power distribution and control systems

-

Building automation and HVAC panels

Their versatility makes them suitable for both signal-level and low-voltage power applications, provided proper specifications are selected.

Design and Safety Considerations

While double-level terminal blocks offer clear advantages, proper selection is essential to ensure safe and reliable operation. Key considerations include:

-

Rated voltage and current for each level

-

Creepage and clearance distances

-

Insulation material performance

-

Compatibility with conductor sizes

-

Mounting stability under vibration

Linhao focuses on precision molding, robust conductive materials, and consistent quality control to ensure that double-level terminal blocks perform reliably in demanding industrial environments.

Long-Term Maintenance and System Scalability

Another often overlooked benefit of double-level terminal blocks is their contribution to long-term system scalability. As systems evolve, additional wiring can be integrated more easily when terminal density is optimized from the beginning.

Maintenance teams also benefit from clearer wiring layers, which reduce accidental disconnections and improve overall service safety.

Why Engineers Choose Linhao for Double-Level Terminal Blocks

With growing demand for compact and efficient wiring solutions, manufacturers must balance innovation with reliability. Linhao has built its reputation by focusing on:

-

Stable mechanical design

-

Consistent electrical performance

-

Industrial-grade materials

-

Application-driven product development

By aligning product design with real-world panel requirements, Linhao supports customers who prioritize efficiency, safety, and long-term reliability in their electrical systems.

Conclusion

Double-level terminal blocks are more than a space-saving component—they are a practical solution to modern wiring challenges. By improving connection density, enhancing organization, and reducing installation complexity, they play a vital role in efficient electrical system design.

For engineers and manufacturers working with compact panels and complex wiring demands, choosing the right double-level terminal block can significantly impact both short-term productivity and long-term system performance.

www.nj-linhao.com

Linhao