For brands across food, beverage, personal care, household chemicals, and health products, bottle body labels are not just decorative elements. They are functional components of product communication, regulatory compliance, and brand identity. Understanding why bottle body labels matter helps manufacturers and brand owners make better packaging decisions that translate into real market performance.

First Impressions Begin with the Bottle Body Label

In retail environments, consumers are exposed to dozens, sometimes hundreds, of competing products. Shelf appeal is driven by visual clarity, consistency, and perceived quality. Bottle body labels occupy the largest visible surface area, making them the primary carrier of branding and messaging.

Well-designed bottle body labels help a product stand out by:

-

Communicating brand identity at a glance

-

Highlighting key product benefits clearly

-

Creating visual harmony with bottle shape and material

-

Reinforcing a sense of quality and professionalism

A poorly designed or low-quality label, on the other hand, can undermine even a premium product. Wrinkles, misalignment, fading, or unclear printing send signals of inconsistency and low attention to detail, which directly affects consumer confidence.

Trust Is Built Through Information and Consistency

Consumer trust is closely linked to how information is presented. Bottle body labels serve as the primary platform for conveying essential details, including product name, usage instructions, ingredients, certifications, and compliance markings.

Clear, readable, and well-structured labels contribute to trust by:

-

Making information easy to find and understand

-

Demonstrating transparency in ingredients and usage

-

Ensuring compliance with regulatory requirements

-

Reducing confusion or misinterpretation

In industries such as food and beverages or personal care, accurate labeling is not only a marketing necessity but also a legal requirement. Consistent bottle body labeling across product lines reinforces brand reliability and reduces the risk of customer hesitation.

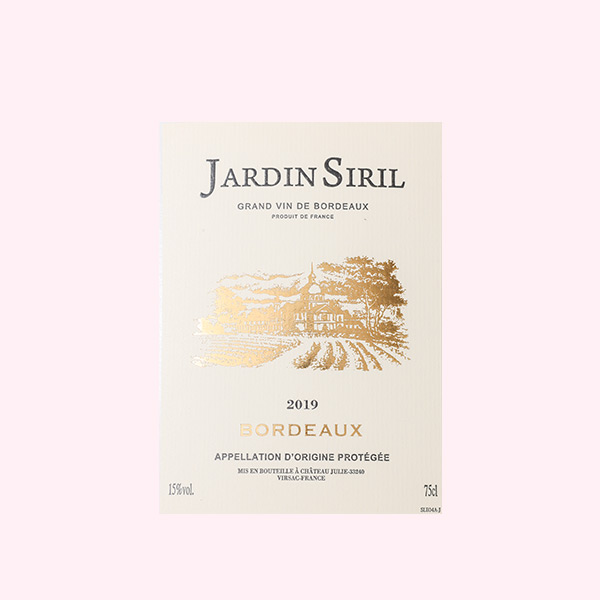

Material Choice Impacts Perceived Quality

Bottle body labels come in various materials, including paper, polypropylene (PP), polyethylene (PE), and specialty films. Each material offers different tactile and visual characteristics that influence how a product is perceived.

For example:

-

Film labels provide durability, moisture resistance, and a clean finish, ideal for beverages and cosmetics.

-

Paper labels can convey a natural or artisanal image when properly finished and protected.

-

Specialty materials enable matte, gloss, or textured effects that elevate shelf presence.

Selecting the right material ensures that the label performs well throughout the product’s lifecycle, from filling and transportation to storage and consumer use. Durable bottle body labels prevent peeling, smudging, or discoloration, preserving brand integrity over time.

Printing Quality Reflects Brand Standards

High-quality printing is essential for effective bottle body labels. Sharp text, accurate colors, and consistent reproduction all signal professionalism and reliability.

Advanced printing technologies allow brands to achieve:

-

Precise color matching for brand consistency

-

Fine detail reproduction for logos and text

-

Special finishes such as embossing or spot varnish

-

High-volume consistency across production batches

When labels are inconsistent or poorly printed, consumers may question the product’s authenticity or quality. Reliable suppliers like Worldbridge focus on maintaining stable printing standards to ensure every label reflects the brand’s intended image.

Functional Performance Matters Beyond Appearance

While shelf appeal is critical, bottle body labels must also perform reliably in real-world conditions. Products may be exposed to moisture, temperature changes, friction during transportation, and repeated handling by consumers.

Functional bottle body labels are designed to:

-

Adhere securely to different bottle materials

-

Resist moisture, oil, and abrasion

-

Maintain legibility throughout product use

-

Integrate smoothly into automated labeling lines

Labels that fail in these areas can cause customer dissatisfaction, returns, or brand damage. Performance-driven design ensures that visual appeal is matched by long-term reliability.

Supporting Brand Storytelling and Differentiation

Bottle body labels are powerful storytelling tools. Through layout, typography, color, and imagery, labels communicate brand values and positioning.

For example:

-

Minimalist designs can emphasize purity or simplicity

-

Bold graphics can signal innovation or energy

-

Natural tones can reinforce sustainability or wellness

By aligning label design with brand messaging, companies create emotional connections with consumers. Over time, this consistency builds recognition and loyalty, which are key drivers of repeat purchases.

The Role of Bottle Body Labels in Automated Production

Modern manufacturing relies heavily on automation. Bottle body labels must be compatible with high-speed labeling equipment to ensure efficiency and consistency.

Professionally engineered labels support:

-

Smooth dispensing without tearing or misalignment

-

Accurate positioning on various bottle shapes

-

Reduced downtime during labeling operations

-

Lower rejection rates in quality control

Worldbridge works with customers to ensure bottle body labels meet both aesthetic and technical requirements, enabling seamless integration into production lines.

For detailed product specifications and professional solutions, you can explore bottle body label options at

Why Supplier Expertise Makes a Difference

Choosing the right bottle body label is not only about design but also about partnering with an experienced supplier. A knowledgeable manufacturer understands material behavior, adhesive performance, printing processes, and industry standards.

An experienced supplier provides:

-

Application-specific recommendations

-

Stable quality control across batches

-

Support for customization and branding needs

-

Reliable delivery for ongoing production

Worldbridge focuses on bottle body label solutions that balance visual appeal, functional performance, and manufacturing efficiency, helping brands compete effectively in demanding markets.

Conclusion

Bottle body labels are far more than packaging accessories. They are essential tools for attracting attention, communicating value, and building consumer trust. From first impression on the shelf to long-term product use, well-designed and well-manufactured labels directly influence how a brand is perceived.

By investing in high-quality bottle body labels and working with an experienced partner like Worldbridge, brands can strengthen shelf appeal, enhance credibility, and create lasting connections with consumers.

www.worldbridgeco.com

WorldBridge